Imagine your IT systems going dark. Reliable power distribution is critical for IT infrastructure. Power problems are a huge deal, causing 45% of incidents by 2025. These outages are expensive too; a single minute can cost businesses $5,600 to $9,000! I believe a basic PDU is essential for any setup. Understanding different models helps you manage power optimally.

Key Takeaways

- Basic PDUs are important for IT systems. They give power to many devices. They help prevent power problems that can cost a lot of money.

- There are many types of basic PDUs. Some fit in racks, some go under desks. You can choose one based on how much space you have and what kind of power you need.

- When you pick a PDU, think about how much power your devices need. Also, check the types of outlets and safety rules. This helps you choose the best PDU for your setup.

Understanding Essential Basic PDU Models

I believe understanding the different types of basic PDU models is key to building a robust power infrastructure. Let’s dive into some of the most common ones you’ll encounter.

Horizontal Rackmount Basic PDU

When I think about power in a server rack, the horizontal rackmount PDU often comes to mind first. These PDUs fit right into your standard 19-inch server rack, usually taking up 1U or 2U of space. For example, a Tripp Lite PDU, like the PDU1220T model, has a depth of 4 inches. I’ve seen others with these typical dimensions:

| Characteristic | Value (cm) | Value (in) | Value (mm) |

|---|---|---|---|

| Width | 44.45 | 17.5 | 445 |

| Height | 4.45 | 1.75 | 44 |

| Depth | 5.72 | 2.25 | 57 |

| Characteristic | Value (kg) | Value (lb) |

|---|---|---|

| Weight | 2.27 | 5 |

These are workhorses in places like data centers and server rooms, where they provide reliable power distribution for high-density setups. You’ll also find them in corporate offices, ensuring seamless power delivery to IT equipment. Telecommunications facilities use them to support critical network infrastructure. They are essential in high-density environments where efficient power management is a must for uninterrupted operations.

Vertical Rackmount Basic PDU

Now, if you’re trying to save space, the vertical rackmount PDU is a game-changer. I call them “Zero-U” PDUs because they don’t take up any horizontal rack space. Instead, you mount them along the side or rear of your server rack. This design preserves valuable horizontal space for your servers and switches. This approach lets you fit more servers and network devices into the same rack footprint. It’s especially useful in high-density data centers.

These vertical units can be quite long. For instance, a 66-inch vertical PDU might have 24 x C13/6 x C19 outlets. Another 66-inch option could offer 24 x IEC C13 outlets. I’ve even seen one with 20 NEMA 5-15R outlets. They come in various sizes, like this common configuration:

| Feature | Detail |

|---|---|

| Length | 1.5 inches |

| Height | 48 inches |

| Width | 1.5 inches |

| Number of Outlets | 24 |

| Receptacle Configuration | NEMA 5-20R |

Under-Desk/Workstation Basic PDU

Moving away from the rack, sometimes you just need power right where you work. That’s where the under-desk or workstation PDU shines. I find these super convenient for my personal setup. They are compact and designed to mount discreetly under a desk or on a wall. They give you easy access to power for your computer, monitors, phone chargers, and other peripherals without a mess of cables on the floor. Their main goal is to provide accessible power outlets in a small, organized footprint for individual users.

Basic Strip PDU

Think of a basic strip PDU as a more robust version of your everyday power strip. I often use these for simpler power distribution needs. They are great for home offices or small business setups. They offer simple and reliable power for office equipment. You’ll find them with various outlet types and cord lengths. For example, some have 16 NEMA 5-15R outlets, with 8 front-facing and 8 rear-facing, and a 10 ft cord. Others might have 12 NEMA 5-15/20R outlets with a 10 ft cord. They are also perfect for temporary or mobile workspaces. Their portability and easy installation make them ideal for flexible power solutions. Here’s a look at some common configurations I’ve seen:

| Model | Outlet Types | Cord Length |

|---|---|---|

| CPS1215RM | 10 NEMA 5-15R | 15 ft (4.6 m) |

| PDU30BT8F8R | 16 – NEMA 5-20R | 12 ft (3.7 m) |

| PDU15B2F10R | 12 – NEMA 5-15R | 15 ft (4.6 m) |

| PDU15B12R | 12 – NEMA 5-15R | 15 ft (4.6 m) |

| PDU20BHVT12R | 12 – IEC-320 C13 | 10 ft (3.0 m) |

| PDU15B10R | 10 – NEMA 5-15R | 15 ft (4.6 m) |

| PDU15B6F12R | 18 – NEMA 5-15R | 15 ft (4.6 m) |

| PDU15B2F12R | 14 – NEMA 5-15R | 15 ft (4.6 m) |

| PDU20BHVT8R | 2 – IEC-320 C19, 6 – IEC-320 C13 | 10 ft (3.0 m) |

| PDU20BVHVT20F | 4 – IEC-320 C19, 16 – IEC-320 C13 | 10 ft (3.0 m) |

Single-Phase Basic PDU

Let’s talk about power phases. A single-phase PDU is what you typically find in homes and small offices. It uses one alternating current (AC) waveform. These PDUs usually handle standard voltages like 120V, 240V, or 120/208V. Their current capacities often range from 15 Amp, 20 Amp, to 30 Amp. In the U.S., 240 volts and 120 volts are standard single-phase options. I’ve noticed that while they were once common in data centers, their use is declining. This is because modern data centers often have high-density equipment that needs more power than single-phase systems can provide. They are mostly used in residential settings with small workloads.

Three-Phase Basic PDU

For bigger power needs, especially in data centers, I always recommend a three-phase PDU. This system uses three AC waveforms, offset from each other. This setup offers significant advantages. For Wye three-phase PDUs, common voltage configurations include 230V/400V and 120V/208V, with the latter being very popular in North America. These PDUs can even provide a second, lower voltage source for smaller devices because they have a neutral line. Standard current capacities are 15, 20, and 30 Amps, but custom options can go up to 400 Amps.

Three-phase PDUs are crucial for high-density data centers. They operate up to 150% more efficiently, which means less energy waste and lower costs. They handle larger loads, which is perfect for high-density environments. I also appreciate their space optimization; they deliver more power while saving valuable rack space. They reduce downtime by balancing loads, minimizing circuit overloads. Plus, they help future-proof your setup and reduce cable bulk, which improves airflow and makes maintenance easier. They offer superior load balancing, energy efficiency, and scalability. This leads to lower operational and installation costs, extending equipment lifespan and ensuring stable operation without voltage drop. For example, a three-phase circuit can deliver 208V at 40A (32A rated) with 11.5kVA, while a single-phase circuit at 208V only achieves 60A (48A rated) with 10.0kVA. This allows for smaller cables and less space. Consolidating with a 400V power circuit can even cut energy costs by 4-5% compared to 120V distribution, supporting high-density racks.

High-Density Outlet Basic PDU

In today’s crowded data centers, every inch of space counts. That’s why I’m a big fan of high-density outlet PDUs. These PDUs are specifically designed to combat limited physical space in data center racks. They are the smallest form factor PDUs available. I’ve seen High Density Outlet Technology (HDOT) PDUs fit as many as 42 C13 outlets in a 42U high network managed PDU. This makes them over 20 percent smaller than comparable PDUs using standard outlets. This design allows them to support more rack components per form factor, significantly increasing real estate within your racks. They really help improve space efficiency and organization.

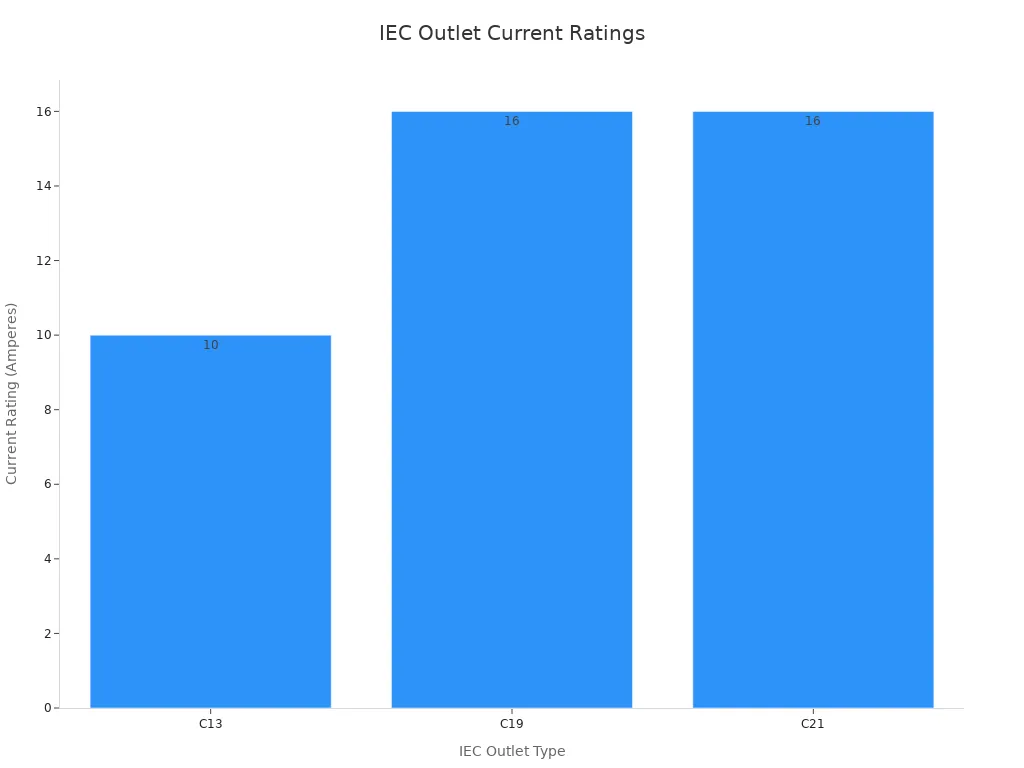

IEC Outlet Basic PDU

When we talk about international standards for power connectors, IEC outlet PDUs come to mind. These are common worldwide, especially in IT equipment. I often see C13 and C19 outlets. C13 outlets are standard for IT equipment and typically rated for 10 Amperes at 250 AC Volts. C19 outlets handle higher power demands, rated for 16 Amperes at 250 AC Volts, and have a larger design. Here’s a quick overview of common IEC outlet types and their ratings:

| IEC Outlet Type | Current Rating (Amperes) | Voltage (Volts) | Notes |

|---|---|---|---|

| C13 | 10 | 250 AC | Standard IT equipment |

| C19 | 16 | 250 AC | Higher power demands, larger design |

| C21 | 16 | 250 DC | Specialized equipment requiring DC power |

You’ll find these PDUs widely used in data centers and server rooms to power numerous server racks. They are also in industrial applications, like automation systems, and even in offices and workstations. Their global compatibility makes them popular for international-purpose devices.

NEMA Outlet Basic PDU

In North America, NEMA outlet PDUs are the standard. These are the familiar plugs and receptacles you see every day. There’s a wide variety of NEMA types, each designed for specific voltage and amperage. For example, the L5-15R is for 125V at 15 Amperes, while an L5-30R handles 125V at 30 Amperes. I’ve put together a table of some common NEMA types and their specifications:

| NEMA Type | Voltage | Amperage |

|---|---|---|

| L5-15R | 125V | 15 Amperes |

| L5-20R | 125V | 20 Amperes |

| L6-15R | 250V | 15 Amperes |

| L7-15R | 277V AC | 15 Amperes |

| L5-30R | 125V | 30 Amperes |

| L6-30R | 250V | 30 Amperes |

| L7-30R | 277V AC | 30 Amperes |

| L8-30R | 480V AC | 30 Amperes |

| L9-30R | 600V AC | 30 Amperes |

| L10-20R | 125/250V | 20 Amperes |

You’ll find NEMA outlet PDUs predominantly in North America and other regions following NEMA standards. They power a vast range of equipment, including servers, network devices, and telecom equipment. They are also used for things like dryers, electric vehicles, and generators.

Surge Protector Basic PDU

Finally, let’s talk about protection. A surge protector basic PDU is essential for safeguarding your valuable electronics from power spikes. I always recommend using one, especially for sensitive server equipment. These PDUs absorb excess voltage, preventing it from reaching your devices. The effectiveness of a surge protector is often measured in joules. A higher joule rating means better protection. For instance, a rating of 2000 joules offers robust defense for sensitive server equipment. Here are some recommended joule ratings for different applications:

| Application Scenarios | Recommended Joule Rating (J) |

|---|---|

| Small Electronic Devices (e.g., phone chargers, routers, modems) | 1,000–2,000 |

| Home Entertainment Equipment (e.g., TVs, gaming consoles, audio systems) | 2,000–3,000 |

| High-End Electronics (e.g., high-performance PCs, workstations, professional audio equipment) | 3,000–6,000 |

Key Features of Basic PDU Models

When I pick a power distribution unit, I look at several key features. These features help me make sure I get the right one for my needs.

Power Capacity and Voltage Compatibility

First, I always check the power capacity and voltage. You need to match the PDU to what your equipment needs. For basic PDU models, we measure load capacity in kilovolt-amperes (kVA). In North America, there’s often an 80% limit on capacity. For example, a single-phase PDU with 120V and a de-rated input of 12A (80% of 15A) would handle 1.44 kVA. I also look at voltage compatibility. Many PDUs handle an input voltage of 230 V AC, with a range from 208 V AC to 240 V AC. They can output 208 V AC or 240 V AC.

Outlet Types and Quantity

Next, I consider the outlet types and how many I need. Different devices use different plugs. I make sure the PDU has the right kind and enough outlets for all my gear.

Form Factors and Mounting Options

I also think about where the PDU will go. Horizontal and vertical rackmounts are common, but I might need an under-desk unit. The form factor and mounting options are important for fitting it into my space.

Build Quality and Materials

Durability matters a lot to me. I want a PDU that lasts. Good ones often use heavy-gauge steel or aluminum. They might also have a powder-coated finish. This helps them resist corrosion and wear.

Surge Protection and EMI/RFI Filtering

Finally, I always look for protection features. Surge protection keeps my electronics safe from power spikes. I also value EMI/RFI filtering. These filters block unwanted electrical signals on power lines. This gives my devices cleaner power. It helps prevent data corruption and system errors. This feature makes my setup more reliable and efficient.

How to Choose the Right Basic PDU

Choosing the right power distribution unit can feel like a big decision. I know it’s important to get it right for your setup. Let me walk you through how I approach this.

Assessing Your Power Requirements

First, I always figure out my total power needs. This is super important. I look at the wattage demands of all my IT equipment. Then, I add in the power my cooling system uses. I also consider any other supporting infrastructure. I always build in a buffer for redundancy and future growth. It’s like planning for extra guests at a party; you want enough food!

I also think about different power considerations. For example, there’s standby power, which includes things like leakage currents, die size, temperature, and process variations. Then, I consider dynamic power. This involves internal nodes changing logic levels and charging/discharging internal capacitances. Architectural resources like RAM blocks, DSP-multiplier blocks, and clock tree networks also use dynamic power. I/O power is another factor. This covers charging and discharging external load capacitors and output driver circuits. I also think about inrush current, which is the power needed when devices first turn on. Configuration power, for setting up devices, is also on my list. Finally, I consider VCCPD, the power supply for output predriver circuitry.

Determining Necessary Outlet Types and Quantities

Next, I look at the outlets. I determine the number and type of outlets I need for all the equipment in my rack. IEC C13 outlets are very common, but I might need other types too. I always include a few extra outlets. This helps me accommodate future growth without overloading the PDU. I also think about the length of a vertical PDU. Longer ones usually have more outlets. Basic vertical PDUs often have 40 or more outlets in a staggered setup.

I also calculate the total wattage of my devices. This helps me pick a PDU with enough power capacity. I make sure the PDU offers the correct number and type of outlets for my equipment. I assess how many devices I plan to connect. I also check the specific types of outlets I need, like NEMA, IEC, or universal connectors. Sometimes, I choose a unit that has a mix of outlet types. This helps me connect different devices easily.

Evaluating Form Factor and Installation Needs

I always think about where the PDU will go. Will it be in a rack, under a desk, or somewhere else? Horizontal and vertical rackmounts are popular choices. But sometimes, an under-desk unit works best for my workstation. The form factor and mounting options are key. They help me fit the PDU perfectly into my space.

Considering Budget and Future Scalability

Budget is always a factor, but I try not to let it be the only one. I balance the cost with my future needs. I think about how my setup might grow. Will I add more equipment later? A slightly more expensive PDU now might save me money and hassle down the road. I want a solution that can scale with me.

Understanding Safety and Compliance Standards

Finally, I always check for safety certifications. These are super important for peace of mind. For example, in the US and Canada, I look for UL Listed. This means the product meets safety standards from Underwriters Laboratories. In the European Union, I check for the CE Mark. Electronic devices need to meet CE standards to be sold there. The LVD (Low-Voltage Directive) also covers electronic equipment in the EU.

Globally, I often see the IEC CB Scheme. This is an international standard for electronic equipment safety. IEC 60950-1 and IEC 62368-1 are specific IEC standards for PDUs. IEC 62368-1 is now compulsory and focuses on product safety during design. PDUs should also comply with FCC Part 15 (Class A). This ensures their electromagnetic emissions don’t interfere with other devices. In Great Britain, I look for the UKCA Mark. It generally follows the CE scheme. I also check for RoHS certification. This confirms the product is free from hazardous substances. These certifications tell me the basic PDU is safe and reliable.

Choosing the right basic PDU is super important for your IT infrastructure. I showed you how different models, like horizontal or vertical, fit specific power distribution needs. Now, you can make smart choices for a strong and reliable power setup. This helps keep your IT running smoothly.

FAQ

What is a basic PDU?

I see a basic PDU as a power strip for IT gear. It distributes electricity to multiple devices. It keeps your equipment running smoothly.

Why do I need a basic PDU instead of a regular power strip?

I find basic PDUs more robust. They offer better power distribution for IT equipment. They often have features like surge protection. Regular power strips are not built for this.

Can I mix NEMA and IEC outlets on one PDU?

Yes, I often see PDUs with both. This lets you connect different types of equipment. Just make sure the PDU’s total capacity handles all your devices.

Post time: Nov-18-2025