The right OEM/ODM PDU Manufacturer offers advanced technology, robust customization, and proven reliability. These capabilities directly impact your operational efficiency. This guide will walk you through the essential steps to make that critical PDU choice for your business success. We will consider basic PDU, metered PDU, or even a smart PDU.

Key Takeaways

- Understand your PDU needs for today and tomorrow. Look for features like power monitoring, remote control, and scalability to support future growth.

- Choose an OEM/ODM PDU manufacturer carefully. Check their technical skills, customization options, quality certifications, and production ability.

- Build a strong partnership with your chosen manufacturer. Good communication, strong support, and a clear contract are important for success.

Understanding Your 2025 PDU Needs and Future-Proofing with an OEM/ODM PDU Manufacturer

When I think about choosing the right PDU, I know it’s not just about what I need today. It’s about looking ahead to 2025 and beyond. My goal is to find a solution that grows with me, not one I’ll outgrow in a year.

Defining Specific PDU Requirements

First, I need to get really clear on what my PDU needs are right now. For data centers and industrial applications, I’m looking for critical specifications. I want detailed insights into power usage, so power monitoring is a must. This helps me stay compliant and understand where my energy goes. Remote control is also super important because it lets me manage things from anywhere, boosting my operational efficiency. I also need environmental tracking to keep an eye on conditions and ensure optimal performance. And, of course, I want energy efficiency support to meet those 2025 energy standards.

I also consider the power capacity and scalability. I evaluate my total power demand, including AC/DC input requirements, and always anticipate future growth with modular designs. Smart PDUs are great because they track energy consumption in real-time, giving me insights into voltage, current, and usage trends. They can even automate tasks like load balancing and power sequencing. It’s also crucial to ensure the PDU integrates seamlessly with my existing infrastructure. This means matching the voltage, current ratings, and connector types of my current systems.

When I think about form factors, I know PDUs come in a few main types. There are floor-standing units, which are usually larger, three-phase units in their own cabinet. I often see these distributing power to individual racks or groups of racks. Then there are rackmount PDUs. These are designed for standard server racks and handle a lot of power. I can mount them vertically in the back of a rack to save space, or horizontally, taking up 1U or 2U. Some models even wall-mount or attach to the side of an equipment rack, which saves physical rack space but might increase the distance to connected devices.

I also consider where these PDUs will be used. In data centers, they’re essential for servers, networking equipment, and critical infrastructure. They manage loads, enable redundancy, and prevent overloads. For IT and server rooms, they power multiple devices and keep power distribution organized and protected. Telecommunications relies on them for continuous uptime, and industrial facilities use them for safe and efficient power to machinery. Commercial buildings, healthcare settings, retail, and education environments all have their specific needs too.

Anticipating Technological Trends for PDU Solutions

Looking to 2025, I see some exciting trends in PDU technology. I expect a big demand for PDUs that offer granular power monitoring and remote management. I want to track power consumption at individual outlet levels, giving me insights into energy use and helping me spot inefficiencies. These PDUs will have advanced metering for voltage, current, power, and power factor with high accuracy.

I also see intelligent PDUs becoming key components of Data Center Infrastructure Management (DCIM) platforms. This integration allows for centralized monitoring, control, and automation of data center resources. It helps with capacity planning, risk management, and operational efficiency through interoperability with various DCIM software using protocols like SNMP, REST APIs, and Modbus.

Remote outlet switching capabilities are also a game-changer. This feature lets me power cycle individual devices remotely, which is super helpful for troubleshooting in edge computing environments or geographically dispersed data centers. It really cuts down on technician travel costs and downtime.

Cybersecurity is paramount as PDUs get more connected. I expect manufacturers to invest in features like encrypted communications, secure boot processes, multi-factor authentication, and regular security patching. I’ve heard that annual investment in PDU cybersecurity features is projected to exceed $500 million by 2025, which tells me it’s a serious focus.

I’m also seeing AI and machine learning making their way into power management. AI algorithms in intelligent PDUs can predict power anomalies, optimize cooling based on load, and automate load balancing to prevent overloads. This offers predictive analytics to prevent costly outages. The rise of edge computing also means I’ll need compact, intelligent PDUs that offer the same remote management and monitoring capabilities as larger data center ones, but adapted for smaller, remote deployments.

Modern PDUs use smart monitoring and remote control to boost data center efficiency and reduce downtime. They integrate IoT technology for real-time monitoring of power usage, temperature, and humidity. This gives me insights into consumption patterns and supports advanced features like power factor correction and load balancing, helping me reduce wasted energy and make proactive decisions.

Scalability and Flexibility for Growth with an OEM/ODM PDU Manufacturer

When I plan for the future, scalability is a top priority. I want to ensure my PDU solution can handle future power demands and equipment upgrades. One of the best practices I consider is adding new connectors, cables, and busways. This means replacing cables and connectors with high-capacity options, using thicker, more heat-resistant cables, and implementing busways with modular tap-offs for flexible high-voltage feed routing.

I also focus on rack and airflow management. I design for increased rack depth, higher weight ratings for dense compute nodes, and integrated airflow and containment features to manage thermal output. Streamlining flooring and cable pathways is also key. I engineer raised floors and cable trays to handle added weight and volume of larger conductors, ensuring enough space in overhead and underfloor pathways for thicker cables.

Integrating with Data Center Infrastructure Management (DCIM) is crucial. I maximize the value of intelligent PDUs by integrating them into my facility’s DCIM platform. This gives me a comprehensive view of power, cooling, and capacity metrics, enabling power usage effectiveness tracking and capacity forecasting.

Planning for scalability means I account for future growth in power requirements. I estimate future needs based on projected growth, considering additional equipment, increased workloads, and evolving technology. I choose PDUs with higher capacity than my current needs and ensure compatibility with existing infrastructure, including features like remote monitoring and environmental sensors.

Incorporating redundancy is another best practice. I design my power distribution setup to include backup PDUs or uninterruptible power supplies (UPS) for critical systems. This often means using dual PDUs per rack and continuous monitoring with smart PDUs.

I regularly review my power requirements. I conduct periodic assessments to ensure ongoing accuracy, monitoring power consumption of all connected devices using metered or smart PDUs. I adjust my plans based on changes in infrastructure or load, updating calculations and upgrading PDUs if necessary.

Using reliable tools, like trusted 3-phase PDU calculators, helps me accurately determine power requirements, minimize errors, and ensure the system operates within safe limits. I look for user-friendly interfaces and advanced functionalities like phase-wise load distribution and derating factors.

Finally, I always collaborate with experts. Consulting with electrical engineers or data center specialists gives me insights, helps optimize power distribution, ensures compliance, and guides me in selecting appropriate tools and equipment. I involve them early in the planning process and leverage their advice.

PDU power distribution units enhance scalability by allowing easy expansion or reconfiguration to accommodate new devices as my business grows, without needing a complete overhaul of the electrical infrastructure. This adaptability makes them a wise investment for future-proofing my electrical systems. An OEM/ODM PDU Manufacturer can provide the modular and scalable solutions I need, supporting automation, remote control, and centralized administration across distributed environments.

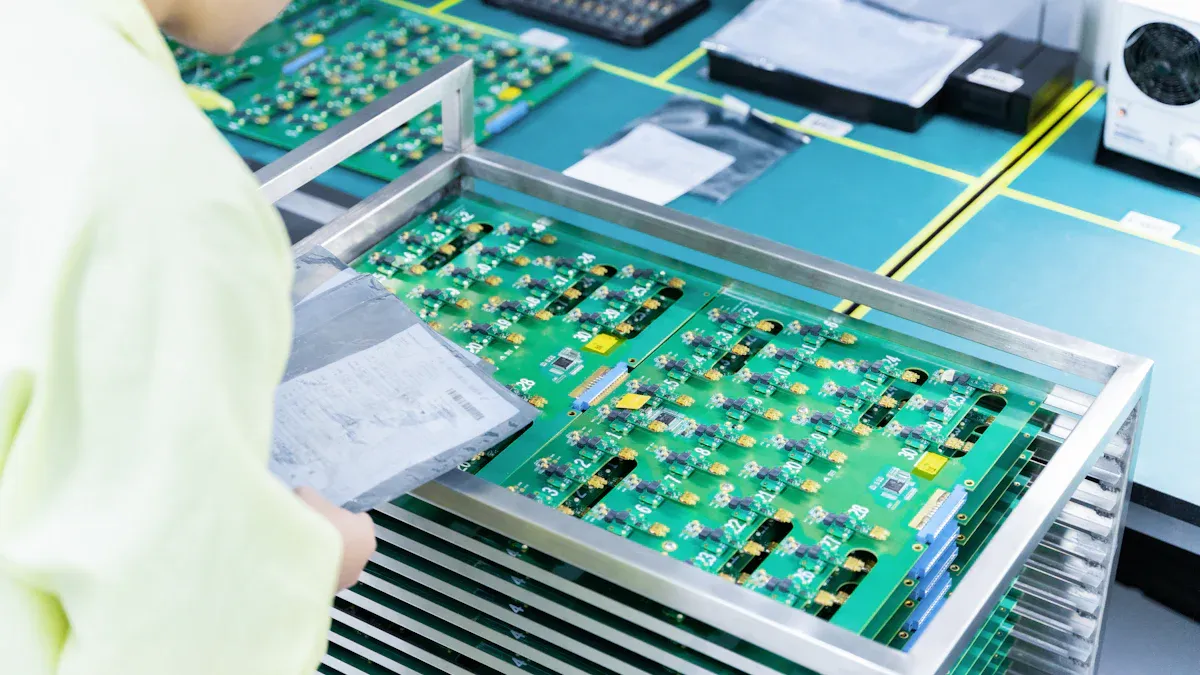

Evaluating OEM/ODM PDU Manufacturer Capabilities and Expertise

After I understand my PDU needs, I shift my focus to the manufacturers themselves. I need to know if they have the skills and experience to deliver what I need. This means looking closely at their technical abilities, how they handle customization, their quality standards, and their production muscle.

Technical Proficiency and R&D Investment

I always look for a manufacturer that shows strong technical proficiency. This means they really understand power distribution technology. I want to see evidence of their investment in research and development (R&D). A company that puts money into R&D is usually at the forefront of innovation. They are developing new features and improving existing ones. This commitment tells me they are serious about staying competitive and offering advanced solutions. I expect them to have engineers who can tackle complex power challenges. Their technical team should be able to explain their product’s inner workings clearly. This helps me trust their expertise.

Customization and Design Flexibility (OEM vs. ODM)

When I choose a PDU manufacturer, I think about how much control I need over the product’s design. This is where understanding the difference between OEM and ODM becomes super important.

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Design Control | Total control over features, specifications, and materials, allowing for unique products tailored to customer demands. | Limited to minor changes like color adjustment, logo addition, or packaging alteration. |

| Innovation & Differentiation | Ideal for businesses focused on innovation and creating distinct products. | Less emphasis on profound technical contribution; suitable for rapid branding. |

| Product Uniqueness | Products are truly your own, reflecting specific brand values and objectives. | Products are often white-label, with limited differentiation beyond surface-level changes. |

I find that OEM customization offers a lot of flexibility. It lets me specify every detail, from the materials used to the overall look. This ensures the PDU perfectly matches my brand values and objectives. It’s especially good for products that need unique features or need to stand out in a crowded market. Working with an OEM helps me innovate and push design boundaries. This results in products that are truly distinct and offer special value to my customers.

On the other hand, ODM is more rigid when it comes to design changes. It offers less flexibility compared to OEM. An ODM handles both the design and production. They offer white-label products that many brands can rebrand. This can save me R&D costs, but it really limits how much I can customize. ODM is great for generic products where saving money and getting to market fast are more important than extensive customization. For product differentiation, the OEM model gives me the design control I need. This helps me create a distinct brand identity. This is crucial in industries where uniqueness is a big advantage. ODM usually only allows surface-level changes, like adding a logo or changing a color. This makes it hard to make my products truly different from competitors.

I also consider specific design flexibility options for specialized PDU applications. For example, I look for:

- Cx Outlets: These combine C13 and C19 functions. They reduce complexity and costs if my equipment changes.

- High-Density Outlet Technology: This offers the most outlets while still meeting IEC C13 and C19 specifications. They also have high retention.

- Alternating-Phase Outlets: These simplify load balancing and improve airflow. They use alternating wiring for 3-phase power.

I also think about the enclosure materials.

- For industrial environments, I need rugged casings. These are made from heavy-duty steel or reinforced materials. They can withstand vibrations and impacts.

- For outdoor telecommunications, I look for corrosion-resistant materials. Stainless steel (grades 304 or 316) or aluminum alloys protect against harsh weather, salt, and humidity.

- For portable designs, I prefer lightweight enclosures. These are built from durable plastics or metals for easy transport.

Other important outlet features include:

- Combination Outlets: These let me connect different plug types in the same receptacle. This offers flexibility for changing equipment setups.

- Alternating Outlets with Color Coding: These simplify circuit/phase balancing and cable management. They help prevent circuit overloads.

- Locking Outlets: These secure the physical connection between my IT equipment and the PDU. They prevent accidental disconnections.

Quality Control and Certification Standards for OEM/ODM PDU Manufacturers

Quality control is non-negotiable for me. I need to know that the PDUs I get are reliable and safe. I always check for a manufacturer’s quality control processes. This includes their testing procedures and how they ensure consistency. Certifications are also a big deal. They show that a product meets specific safety and performance standards.

I look for several international certifications:

- FCC Certification: This is mandatory for electronic devices that emit radio frequency energy in the United States. It ensures electromagnetic compatibility and prevents interference.

- CE Marking: This is the European Union’s approval. It means products comply with health, safety, and environmental standards. It allows free movement of goods within the EU.

- UL Certification: This is a widely recognized safety mark in North America. Retailers and insurers often require it. It proves rigorous testing against risks like fire and electrical shock.

- RoHS Compliance: This directive, from the EU, restricts hazardous substances in electronics. Similar regulations exist globally to reduce environmental and health risks.

Depending on where I plan to sell or use the PDUs, other certifications might be necessary. These include CCC (China), KC Mark (Korea), PSE Mark (Japan), and BIS Certification (India). I make sure the OEM/ODM PDU Manufacturer can provide all the relevant certifications for my target markets.

Production Capacity and Lead Times of an OEM/ODM PDU Manufacturer

Finally, I assess a manufacturer’s production capacity and lead times. I need to know they can handle my order volume. I also need to know they can deliver on schedule. This is especially true for custom PDU orders.

- For standard PDUs, lead times typically range from 4 to 8 weeks.

- For custom PDUs, the lead time will not exceed 28 weeks for quantities under 250 pieces.

I also consider Minimum Order Quantities (MOQs).

- Basic PDUs usually have an MOQ starting at 100-500 units.

- More customized PDU designs might require MOQs of 1,000+ units.

I also ask about sample lead times. For standard units, these are typically 7-15 days. Understanding these factors helps me plan my projects effectively and avoid delays.

Assessing Partnership and Support from an OEM/ODM PDU Manufacturer

After I understand what I need, I look at the manufacturer. I want to know if they can be a good partner. This means checking their support and how they work with customers.

Communication and Responsiveness

Good communication is super important to me. I need a manufacturer who talks clearly and often. Close collaboration between my company and the manufacturer is essential. We need to share information and agree on goals. This helps us make great products. Effective communication ensures clarity. It helps solve problems fast during the whole project. I also look for great customer support. They should be available and quick to respond. This is key for setup and troubleshooting. I like 24/7 support. It means they are always there, no matter the time zone. Quick answers show they care about customers. Comprehensive resources like manuals and online tutorials also help a lot.

Post-Sales Support and Warranty

What happens after I buy? That’s what I think about next. I need strong post-sales support and a good warranty. Many top PDU companies offer reliable customer support. They have global networks. They give technical help around the clock. You can reach them by phone, email, or live chat. Some brands even have special portals for troubleshooting. For example, APC by Schneider Electric has 24/7 support centers. Vertiv sends engineers for on-site service. Legrand offers support in many languages. I also see that PDUeX PDUs come with a standard two-year warranty. You can buy extended warranty support too.

Cost-Effectiveness and Total Cost of Ownership

I always look beyond the price tag. I think about the total cost of ownership. Smart PDUs can save a lot of money. Many organizations cut energy use by up to 20% after installing them. For example, a mid-sized data center can save about $50,000 each year on energy. Smart PDUs can give me up to 15% energy cost savings for small operations. Large ones can see up to 20%. They also add 2-3% more savings. Some even get 30% better energy efficiency. These PDUs also reduce downtime by up to 30%. This means my systems stay running more often. Investing in smart PDUs pays off fast. It often takes just a few months. This is because of big energy savings and less downtime.

Reputation and References of an OEM/ODM PDU Manufacturer

Finally, I check their reputation. I ask for references. I want to talk to other customers. What was their experience like? Did the manufacturer deliver on time? Was the quality good? A strong reputation means they are reliable. It shows they stand by their products. I also look at online reviews and industry feedback. This helps me feel confident in my choice.

The Selection Process: Partnering with the Right OEM/ODM PDU Manufacturer

Initial Research and Shortlisting

When I start looking for a partner, I begin with broad research. I search online, check industry directories, and ask for recommendations. My goal is to find companies with a good track record in PDU manufacturing. I look for those that seem to align with my needs for quality and innovation. Then, I create a shortlist of potential partners. These are the ones I want to investigate further.

Request for Proposal and Detailed Quotations

After shortlisting, I send out a Request for Proposal (RFP). This document clearly outlines my project. It includes my product specifications and the scope of work. I also provide my estimated volumes and target product cost. I expect the OEM/ODM PDU Manufacturer to respond with a detailed quotation. This should cover pricing, timelines, and how they plan to meet my quality requirements. I also ask for their supplier selection criteria and any required extra operations.

On-Site Audits and Sample Testing

I believe seeing is believing. So, I always conduct on-site audits of the manufacturing facilities. This lets me check their quality control and production processes firsthand. I review specific SOPs for things like employee training and equipment calibration. I also look at their GMP compliance. This includes checking their physical plant, equipment, and production controls. I also request samples of their PDUs. I test these samples rigorously to ensure they meet my performance and reliability standards.

Contract Negotiation and Partnership Agreement

The final step is negotiating the contract. This agreement defines our partnership. I focus on key terms like the scope of work and quality standards. We discuss pricing and payment terms. Intellectual property rights are very important to me. I make sure these are clearly defined. We also set production timelines and delivery expectations. Finally, we include clauses for liability, warranty, and how we will resolve any disputes.

Choosing the right PDU partner in 2025 is a big strategic move. I know it takes careful research, clear talks, and looking ahead. By really checking out their skills, knowing what I need, and building a strong partnership, I can get a PDU solution that helps my business grow and succeed for a long time.

FAQ

What is the main difference between OEM and ODM for PDUs?

I see OEM gives me full design control for unique products. ODM offers pre-designed products with limited customization, like adding my logo.

Why are certifications like UL and CE important for PDUs?

I know certifications prove PDUs meet safety and performance standards. They ensure my products are reliable and safe for different markets.

How does scalability benefit my PDU choice?

I find scalability lets my PDU system grow with my business. It means I can add new devices without a full electrical overhaul.

Post time: Dec-10-2025