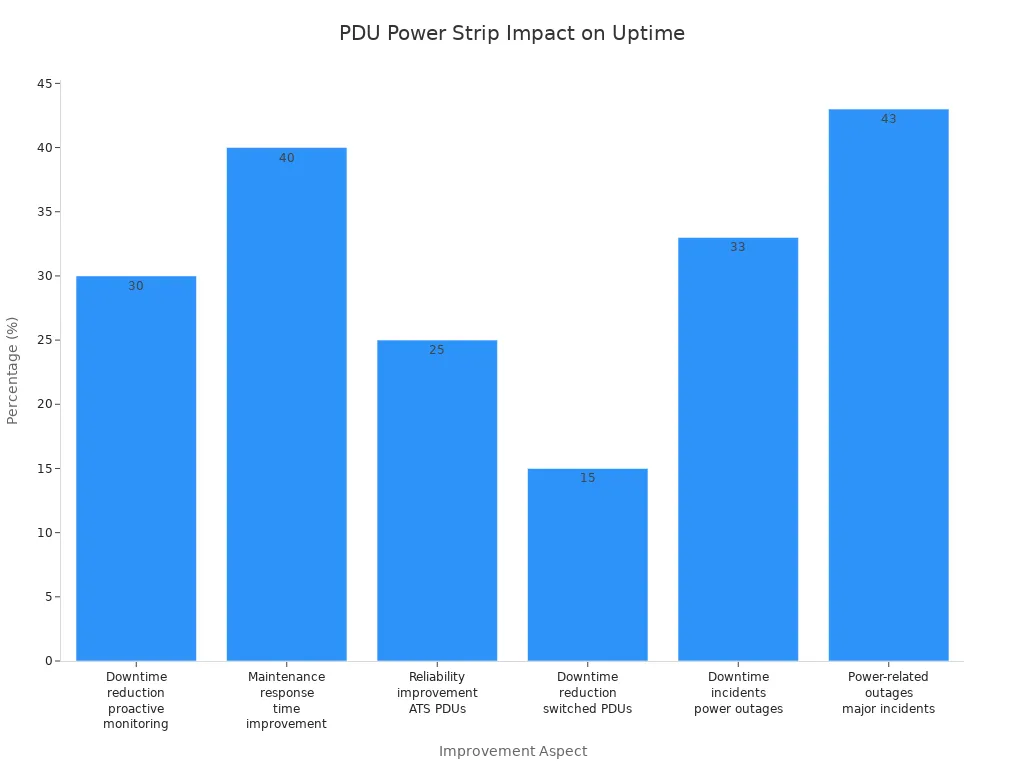

A PDU power strip delivers stable, protected power to every device in a modern server room. Power-related issues cause more than half of severe outages in data centers, according to the Uptime Institute’s 2025 report. Operators consistently identify power failures as the main threat to uptime, with 54% of downtime traced to electrical disruptions. By supporting proactive monitoring and balanced load distribution, a PDU power strip can reduce downtime by up to 30%.

Key Takeaways

- A PDU power strip delivers stable, reliable power to multiple devices in server rooms, preventing outages and supporting continuous operation.

- Different types of PDUs—from basic to intelligent—offer varying levels of monitoring, control, and protection to match specific server room needs.

- Advanced PDUs balance electrical loads and provide real-time monitoring to reduce downtime by detecting and preventing overloads early.

- Surge protection and built-in circuit breakers in PDUs safeguard sensitive equipment from voltage spikes and electrical faults.

- Redundancy features like dual power inputs and automatic transfer switching ensure continuous power during failures or maintenance.

- Smart PDUs enable remote monitoring, outlet-level control, and environmental sensing, helping IT teams manage power efficiently and prevent issues.

- Regular maintenance, including visual inspections and load testing, keeps PDUs operating safely and reliably over time.

- Choosing the right PDU involves assessing power needs, outlet types, capacity, and advanced features while ensuring quality certifications for safety.

What Is a PDU Power Strip?

Definition and Core Purpose

A PDU power strip serves as a specialized device that distributes electrical power to multiple pieces of equipment in a server room or data center. Unlike standard power strips, it manages higher electrical loads and supports critical IT infrastructure. Operators rely on PDUs to ensure each server, switch, and storage device receives stable, reliable power. This approach helps prevent outages and supports continuous operation.

Key Components and Design

A typical PDU power strip contains several essential components that contribute to its performance and reliability. The table below outlines these components and their roles:

| Component Type | Description / Role |

|---|---|

| Power Outlets (C13, C19) | Provide multiple connection points for devices, enabling power distribution to many devices in a rack. |

| Power Input (Single/Three-phase) | Determines the type and amount of power the PDU can receive and distribute, supporting different power loads. |

| Mounting Options (Rackmount, Floor Standing) | Physical installation methods that affect space usage and deployment flexibility in data centers. |

| Monitoring & Management Features (Basic, Metered, Monitored, Switched) | Enable power consumption tracking, remote control, and outlet management to improve efficiency and safety. |

| Network Connectivity | Allows remote access and control of the PDU for monitoring and management purposes. |

These components work together to deliver efficient power distribution, enable remote management, and improve operational reliability. Many PDUs also feature modular designs, allowing for customization based on the needs of the server room.

Types of PDU Power Strips

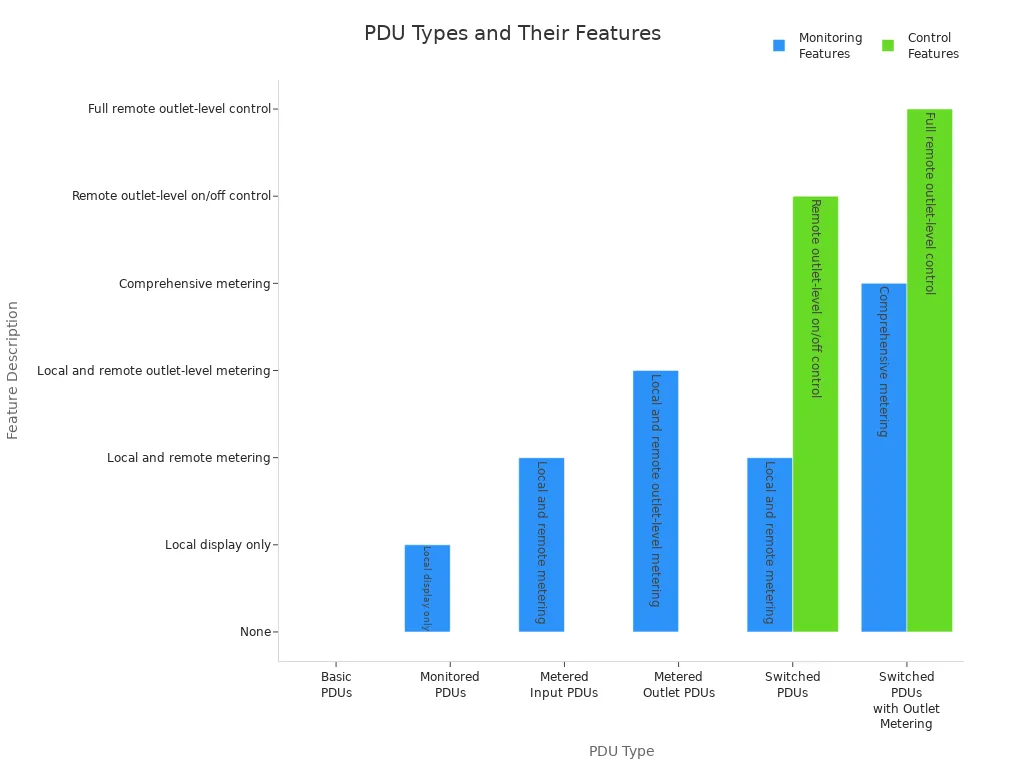

Data centers use several types of PDU power strips, each designed for specific requirements. The main types include:

Basic PDU Power Strips

Basic PDUs provide simple power distribution without monitoring or control features. They suit small or non-critical environments where advanced management is not required.

Metered PDU Power Strips

Metered PDUs display real-time power usage data through a local display. Operators can monitor power consumption on-site, which helps prevent overloads and supports safe operation.

Switched PDU Power Strips

Switched PDUs combine monitoring with remote on/off control at the outlet level. This feature allows operators to power cycle equipment remotely, improving troubleshooting and efficiency.

Intelligent (Smart) PDU Power Strips

Intelligent PDUs, sometimes called smart PDUs, offer advanced features such as remote monitoring, outlet-level metering, and environmental sensors. These units support network connectivity, enabling real-time alerts and integration with management software.

Tip: Intelligent PDUs help data centers maximize uptime by providing detailed power usage data and remote management capabilities.

Each type of PDU power strip addresses different operational needs, from basic distribution to comprehensive power management. Selecting the right type ensures the server room remains efficient, safe, and prepared for future growth.

How a PDU Power Strip Prevents Downtime

Reliable Power Distribution

Even Load Distribution

Server rooms demand consistent power delivery to every device. A PDU power strip ensures even load distribution across all connected equipment. By allocating power evenly, it prevents any single circuit from becoming overloaded. This balanced approach not only extends the lifespan of critical hardware but also reduces the risk of sudden outages.

| Benefit Description | Quantitative Improvement |

|---|---|

| Reduction in unintentional power outages | 15% |

| Reliability increase with advanced PDUs (e.g., ATS) | 25% |

| Improvement in maintenance response times | 40% |

Advanced features such as load balancing and real-time monitoring contribute to these improvements. Operators can quickly identify and resolve potential issues before they escalate, minimizing the risk of downtime.

Reducing Circuit Overload Risks

Circuit overloads remain a leading cause of server room failures. Intelligent PDUs monitor current draw at each outlet and alert technicians when loads approach critical thresholds. This proactive monitoring enables staff to redistribute power or shut down non-essential devices, preventing cascading failures.

| Feature | Impact on Reducing Unplanned Server Outages and Reliability |

|---|---|

| Real-time monitoring | Enables proactive detection of power issues, reducing downtime by over 25% |

| Load balancing | Prevents overloads and evenly distributes power, minimizing outages |

| Surge protection | Protects equipment from electrical faults, preventing unexpected failures |

| Remote management | Allows remote reboot and control, reducing physical intervention and downtime |

| Environmental sensors | Monitor temperature and humidity to protect equipment lifespan, indirectly reducing outages |

Note: Real-time monitoring and load balancing are essential for maintaining uptime in high-density server environments.

Surge and Spike Protection

Built-in Surge Suppression

Sensitive electronics in server rooms face constant threats from voltage spikes and surges. Unlike standard power strips, a PDU power strip with integrated surge protection uses components such as metal oxide varistors (MOV) or gas discharge arrestors (GDA) to absorb or divert excess voltage. This design shields connected devices from sudden electrical disturbances.

- Standard power strips only provide multiple outlets and basic overload protection.

- Surge-protected PDUs absorb or divert excess voltage, preventing damage to valuable equipment.

- Surge protectors feature a joule rating, indicating their energy absorption capacity.

- Some models include indicator lights or alarms to signal when protection is no longer effective.

- This level of protection is critical for expensive and sensitive IT hardware.

Protecting Sensitive Equipment

Voltage spikes can cause irreversible damage to servers, switches, and storage arrays. Surge-protected PDUs act as a first line of defense, ensuring that only safe, regulated power reaches each device. Over time, the surge protection capacity may diminish, but indicator lights help operators know when to replace or service the unit.

- Surge-protected PDUs combine efficient power distribution with advanced protection.

- They offer superior equipment safety compared to standard power strips, which lack surge suppression.

- Investing in surge-protected PDUs helps prevent costly downtime and equipment replacement.

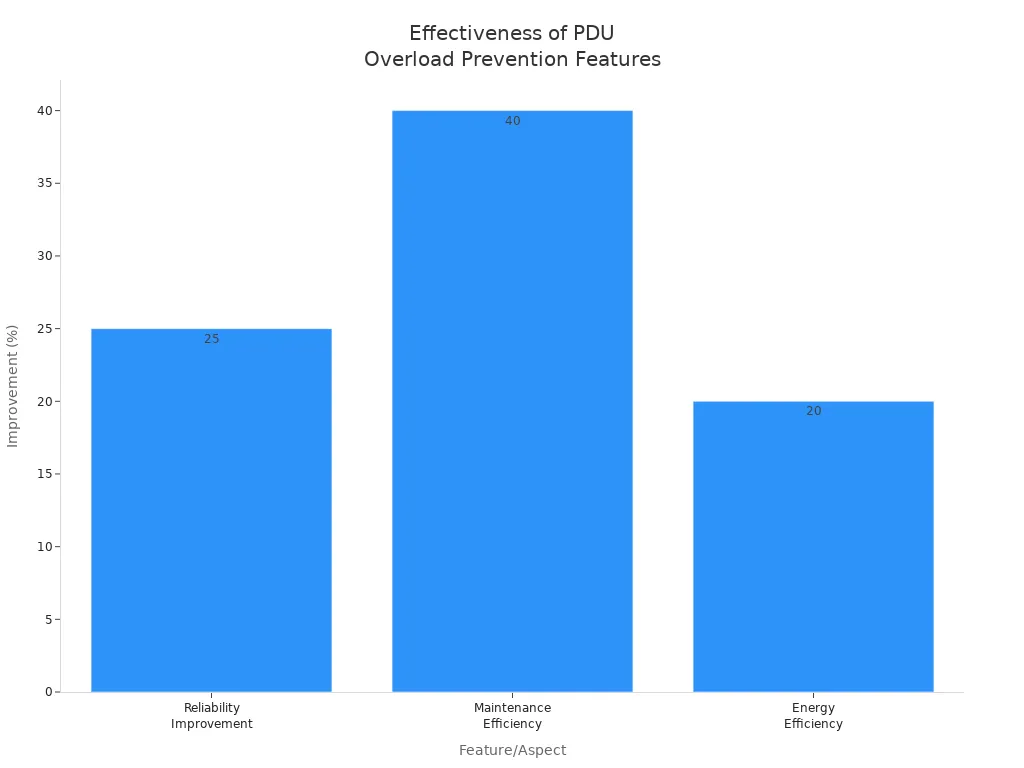

Overload Prevention

Circuit Breakers and Fuses

Overload prevention is a cornerstone of safe server room operation. PDUs designed for professional environments include built-in circuit breakers and fuses. These components automatically disconnect power during overloads or short circuits, preventing electrical hazards and protecting both equipment and personnel.

| Feature/Aspect | PDUs (Power Distribution Units) | Power Strips |

|---|---|---|

| Overload Prevention | Equipped with circuit breakers that automatically disconnect power during overloads or short circuits, preventing electrical hazards. | Basic or no overload protection |

| Monitoring Capabilities | Intelligent PDUs provide real-time monitoring of current, voltage, temperature, and humidity, enabling proactive overload prevention. | Typically no monitoring features |

| Remote Management | Allows remote control and load balancing to quickly respond to overload conditions, improving uptime and reliability. | No remote management capabilities |

| Durability | Built with robust materials (aluminum/steel) and certified (ISO9001, CE, UL) for safety and compliance. | Standard construction, less durable |

| Reliability Improvement | Advanced PDUs increase reliability by approximately 25% in facilities with backup power systems. | N/A |

| Maintenance Efficiency | Remote monitoring improves maintenance response times by about 40%. | N/A |

| Energy Efficiency | Intelligent PDUs can reduce energy consumption by up to 20% through optimized power management. | N/A |

Load Monitoring Features

Intelligent PDUs offer real-time monitoring of current, voltage, and environmental conditions. Operators can access this data remotely, allowing for quick identification of abnormal loads or environmental risks. This capability enables proactive intervention, reducing the likelihood of overloads and improving overall system reliability.

- Real-time monitoring reduces downtime by more than 25% through early issue detection.

- Remote management allows for immediate response, minimizing the need for on-site intervention.

- Environmental sensors integrated into PDUs help maintain optimal operating conditions, further reducing failure risks.

A PDU power strip with these advanced features forms the backbone of a resilient server room, ensuring continuous operation and safeguarding critical IT assets.

Redundancy and Failover

Redundancy and failover features form the backbone of reliable power management in modern server rooms. These mechanisms ensure that critical IT equipment remains operational, even when unexpected power disruptions occur. Data centers and server rooms depend on these features to maintain uptime, protect data, and meet strict service level agreements.

Dual Power Inputs

Dual power inputs provide a robust layer of protection against power source failures. Each PDU can connect to two independent power sources, such as separate utility feeds or backup generators. If one source fails, the other continues to supply power without interruption. This setup, often called N+1 redundancy, guarantees that servers and networking devices receive continuous power.

- Dual power inputs allow seamless transition between power sources.

- Operators can perform maintenance on one power feed without shutting down equipment.

- This configuration reduces the risk of downtime caused by single-point failures.

- Many enterprise-grade PDUs support dual power inputs to enhance reliability.

A table below highlights the benefits of dual power inputs:

| Feature | Benefit |

|---|---|

| Two independent inputs | Continuous power during source failure |

| N+1 redundancy | Increased uptime and operational resilience |

| Maintenance flexibility | No need for equipment shutdown during repairs |

Note: Dual power inputs are essential for mission-critical environments where uptime is non-negotiable.

Automatic Transfer Switching

Automatic Transfer Switching (ATS) technology elevates redundancy by enabling real-time switching between power sources. When the primary source fails or becomes unstable, the ATS instantly transfers the load to the secondary source. This process occurs without manual intervention and typically completes in milliseconds, ensuring that connected devices experience no disruption.

- ATS supports devices that lack dual power supplies, extending redundancy benefits to a wider range of equipment.

- The system monitors both power sources continuously and selects the most stable option.

- Failover occurs automatically, reducing the risk of human error during emergencies.

- ATS-equipped PDUs help prevent outages, data loss, and service interruptions.

Operators in data centers rely on ATS to safeguard continuous operation. By integrating dual power inputs and ATS, facilities achieve higher operational efficiency and power reliability. These features collectively reduce downtime, protect valuable data, and help organizations meet their uptime commitments.

Tip: Combining dual power inputs with ATS ensures that even during component failures or utility outages, servers and network devices remain powered and operational.

Smart Features of a PDU Power Strip for Proactive Management

Modern server rooms demand more than just basic power distribution. Intelligent PDU power strips deliver advanced features that enable IT teams to monitor, control, and automate power management from anywhere. These smart capabilities help prevent downtime, optimize energy use, and support efficient operations.

Remote Monitoring Capabilities

Real-Time Power Usage Data

Intelligent PDUs provide real-time monitoring at both the unit and outlet levels. Operators can track voltage, current, and energy consumption for each device. This granular visibility supports efficient load balancing and helps prevent overloads before they occur.

- Real-time tracking of energy consumption and operational status from any location

- Power usage monitoring at outlet and device level for precise load management

- Detection of power fluctuations to maintain stable distribution

- Centralized power distribution simplifies cable management and energy tracking

These features allow IT teams to make informed decisions, reduce energy waste, and support sustainability goals.

Environmental Monitoring (Temperature, Humidity)

Environmental sensors integrated into PDUs monitor temperature and humidity within the rack. Early detection of abnormal conditions helps protect sensitive equipment from overheating or moisture damage.

- Continuous tracking of temperature and humidity

- Early warnings for potential risks such as overheating or high humidity

- Integration with DCIM software for comprehensive environmental oversight

Note: Environmental monitoring ensures optimal conditions for IT equipment, reducing the risk of failures.

Remote Control and Automation

Outlet-Level Switching

Remote management enables operators to control individual outlets from anywhere. This feature allows IT staff to reboot or power off specific devices without visiting the server room.

| Feature | Benefit |

|---|---|

| Outlet-level control | Remotely turn outlets on/off and reboot devices for quick troubleshooting |

| Power metering | Track energy usage at each outlet for precise management |

| Network connectivity | Access and control outlets via web or mobile apps |

Outlet-level switching streamlines troubleshooting and increases flexibility in managing critical infrastructure.

Scheduled Power Cycling

Automated scheduling allows operators to set power cycles for specific outlets. This capability optimizes energy use and supports routine maintenance without manual intervention.

- Customizable power schedules reduce unnecessary energy consumption

- Automated reboot settings minimize downtime for critical equipment

- Power cycling supports preventive maintenance and operational efficiency

Tip: Scheduled power cycling helps data centers reduce energy waste and extend equipment lifespan.

Alerting and Notifications

Email and SMS Alerts

Intelligent PDUs send real-time alerts via email or SMS when they detect anomalies such as overloads, voltage fluctuations, or environmental risks. These notifications enable immediate response, reducing the risk of outages.

| Alerting Feature | Impact on Operations |

|---|---|

| Real-time alerting | Immediate detection and faster incident response |

| Threshold alerts | Proactive intervention before critical issues arise |

| Auto ticketing | Automated incident reporting for quick escalation |

Integration with Management Software

Integration with Data Center Infrastructure Management (DCIM) or Building Management Systems (BMS) centralizes incident handling and reporting. Operators receive detailed reports and analytics, supporting proactive maintenance and compliance.

- Alerts integrate with management software for centralized oversight

- Predictive analytics and AI-driven detection speed up issue resolution

- Remote management reduces the need for on-site visits, saving time and resources

Callout: These alerting and notification systems improve reliability, reduce downtime, and support compliance with industry standards.

Practical Steps to Ensure Continuous Operation with a PDU Power Strip

Regular Maintenance and Testing

Visual Inspections

Routine visual inspections form the foundation of reliable power management in server rooms. Technicians examine all hardware, switches, circuit breakers, and displays for signs of overheating, dust accumulation, discoloration, or burn marks. They check for loose outlets and verify connection integrity. Cleaning begins only after shutting down power. Specialists use insulated tools and microfiber cloths to remove dust, then disinfect surfaces according to manufacturer guidelines. The cleaning area remains dry and organized, with cables secured to prevent accidents. Surfaces must dry completely before restoring power. These steps help prevent energy loss and reduce the risk of unexpected failures.

Load Testing Procedures

After cleaning, technicians conduct a series of tests to confirm system reliability. They simulate overcurrent events to check circuit breaker response. Monitoring power metrics such as voltage, current, and consumption ensures each outlet delivers consistent power. Waveform analysis detects irregularities, while a multimeter verifies electrical continuity. A troubleshooting checklist addresses issues like frequent overload protection activation or unresponsive outlets. All inspections, cleaning, and repairs are documented. Maintenance frequency adjusts based on environmental conditions, typically every three to six months, with more frequent checks in dusty or high-traffic areas. Safety precautions remain a priority, including disconnecting power, inspecting tools, wearing PPE, and ensuring proper grounding.

Implementing Redundant Power Paths

Dual PDU Power Strips for Critical Equipment

Redundant power paths eliminate single points of failure. Data centers deploy dual power feeds from independent sources, often using separate utility providers or grid connections. Redundant Power Distribution Units distribute electricity efficiently, ensuring critical IT equipment with dual power supplies continues operating during a power source outage. Tier III and IV facilities rely on dual utility feeds and diverse pathways to maintain uptime for mission-critical applications.

Tip: Double-check configurations during installation to ensure each input connects to an independent power source. Regular audits and maintenance help identify vulnerabilities that could compromise redundancy.

UPS Integration

Uninterruptible Power Supply (UPS) systems provide backup power during outages. Integrating UPS units with redundant PDUs ensures continuous electricity supply even if the main utility fails. This combination protects sensitive equipment, supports failover strategies, and maintains operational continuity.

Documentation and Training

Power Mapping

Accurate power mapping supports efficient troubleshooting and future expansion. Teams document the location and configuration of every PDU, outlet, and connected device. This practice simplifies maintenance, helps balance loads, and ensures quick identification of issues.

Staff Training on PDU Power Strip Use

Comprehensive training programs empower staff to manage power infrastructure effectively. Product training and certification programs, such as those offered by industry leaders, help users master equipment operation. User-friendly interfaces and centralized management platforms streamline daily operations. Ongoing support and clear documentation ensure staff can respond quickly to incidents, reducing downtime and improving reliability.

Choosing the Right PDU Power Strip for Your Server Room

Assessing Power Requirements

Calculating Total Load

Selecting the correct power solution starts with understanding the total load. Facility managers identify whether the environment needs an AC-powered or DC-powered unit, based on the power type and connector compatibility. They determine the expected maximum power for each rack by reviewing equipment specifications or using capacity planning tools. This process includes accounting for redundancy and future expansion. Knowing the available voltage supply and the power factor of devices ensures the chosen unit matches the electrical environment. Managers also consider whether devices have single or dual power supplies, which impacts redundancy planning.

Tip: Always plan for a 20-30% safety margin above the calculated total load. This margin prevents overloads and accommodates unexpected power spikes.

Planning for Future Growth

A forward-thinking approach supports long-term reliability. Teams estimate future equipment additions and select units with enough outlets and capacity to handle growth. They also consider the need for remote control of redundant-powered devices, ensuring the ability to power cycle multiple inputs simultaneously. This strategy reduces the risk of outgrowing the power infrastructure and supports seamless upgrades.

Outlet Types and Configurations

Matching Device Plugs

Compatibility between outlets and device plugs is essential. Units offer a range of outlet types, such as NEMA, IEC, and universal connectors. Matching the outlet type to the connected equipment ensures safe and effective operation. For example, a rack with both servers and network switches may require a mix of C13 and C19 outlets.

Number and Arrangement of Outlets

The number and arrangement of outlets must align with current and future needs. Selecting a unit with the correct quantity and configuration allows for efficient cable management and device connection. Different models—basic, metered, or smart—provide varying levels of distribution, monitoring, and management. Additional features like surge protection and filtering further enhance reliability.

| Outlet Type | Typical Use Case | Benefit |

|---|---|---|

| NEMA | North American devices | Broad compatibility |

| IEC C13/C19 | Servers, switches | High-density connections |

| Universal | Mixed environments | Flexible deployment |

Capacity and Form Factor

Rack-Mount vs. Vertical (Zero-U)

Form factor impacts both space and airflow. Vertical (Zero-U) units save valuable rack space and suit high-density environments. Horizontal units occupy rack units but offer easier access for maintenance. Positioning units to avoid blocking airflow supports effective heat dissipation and prevents overheating.

Amperage and Voltage Ratings

Capacity planning includes selecting the correct amperage and voltage ratings. Single-phase units work well for smaller setups, while three-phase models support high-density racks. Managers match input and output plug types to regional standards and equipment requirements. Including surge protectors and circuit breakers safeguards sensitive devices from voltage spikes and overloads.

Note: Regular audits of power usage and rack space help identify underutilized areas and support ongoing capacity planning.

Advanced Features to Consider

Network Connectivity

Modern data centers require more than basic power distribution. Advanced PDUs now offer network connectivity, which transforms power management into a proactive, data-driven process. With network-enabled PDUs, IT teams can monitor and control power usage remotely. This capability allows for real-time adjustments, reducing the need for on-site intervention and improving response times during incidents.

Network connectivity supports protocols such as SNMP and HTTP, enabling seamless integration with existing management platforms. Operators can access detailed reports, set thresholds, and receive alerts from anywhere. This level of oversight helps prevent overloads and supports efficient load balancing. Switched PDUs, for example, allow remote on/off control of individual outlets. This feature decreases operational downtime by approximately 15% and improves maintenance response times by 40%. Intelligent PDUs provide outlet-level monitoring, which reduces power waste by up to 30% and enables precise energy management.

Tip: Network-connected PDUs help organizations align with sustainability goals by tracking energy consumption and identifying opportunities for optimization.

The table below highlights the value of advanced PDU features for modern data centers:

| Advanced Feature | Description | Value to Modern Data Centers |

|---|---|---|

| Intelligent/Smart PDUs | Real-time energy monitoring at outlet level; remote monitoring and control | Reduces power waste by up to 30%; improves energy efficiency; enables load balancing to prevent overloads |

| Switched PDUs | Remote on/off control of individual outlets | Decreases operational downtime by ~15%; improves maintenance response times by 40%; enhances operational flexibility |

| Automatic Transfer Switch (ATS) PDUs | Automatically switch power sources to maintain continuous power | Increases reliability by 25% in backup power configurations; avoids outages in mission-critical environments |

| Surge Protection & Circuit Breakers | Protect equipment from power surges and overloads | Minimizes downtime risks; critical as downtime can cost thousands per minute |

| Three-Phase Power Integration | Supports high power density, load balancing, and scalability | Improves operational performance by 25%; reduces energy losses by 3-5%; supports power outputs >22 kW |

| Environmental Monitoring | Temperature and humidity sensors integrated with intelligent PDUs | Enables data center optimization and sustainability alignment |

| Scalability Features | Designed to support infrastructure growth without major rewiring | Ensures service continuity during expansion; reduces ownership costs over time |

Environmental Sensors

Environmental sensors represent another critical advancement in PDU technology. These sensors monitor temperature and humidity within server racks, providing early warnings for conditions that could threaten equipment. High temperatures or excessive humidity can lead to hardware failures, data loss, or reduced equipment lifespan.

By integrating environmental monitoring with intelligent PDUs, operators gain real-time visibility into rack conditions. Alerts notify staff when readings exceed safe thresholds, allowing for immediate corrective action. This proactive approach helps maintain optimal operating environments and supports compliance with industry standards.

Environmental monitoring also aligns with sustainability initiatives. Data centers can optimize cooling systems based on actual conditions, reducing energy consumption and operational costs. Over time, this leads to improved efficiency and a lower carbon footprint.

Note: Environmental sensors in PDUs enable data centers to protect valuable assets and support long-term operational goals.

The Role of Quality and Certification in PDU Power Strips

Importance of Reliable Manufacturing

Reliable manufacturing forms the backbone of dependable power distribution in server rooms and data centers. Manufacturers who prioritize quality ensure that their products withstand the rigors of demanding environments. This approach minimizes power interruptions and reduces costly downtime.

ISO9001 Certification

ISO9001 certification stands as a global benchmark for quality management systems. Manufacturers who achieve this certification demonstrate a commitment to consistent processes and continuous improvement. ISO9001 ensures that every unit meets strict quality standards, resulting in reliable and high-performing products.

Quality Control Standards

Quality control standards guide every stage of production. Leading manufacturers implement rigorous testing and inspection protocols. These standards guarantee that each unit integrates advanced safety features, such as circuit breakers and surge protection. The result is a product that protects sensitive equipment from electrical faults and power spikes.

Reliable manufacturing delivers several key benefits:

- Durable designs that withstand harsh environments

- Advanced safety features for uninterrupted operations

- Compliance with industry standards, reducing regulatory risks

- Real-time monitoring and remote management for proactive maintenance

- Custom solutions that optimize power management and scalability

- Up to 30% reduction in downtime and significant energy cost savings

- Long-term reliability through partnerships with experienced manufacturers like YOSUN

Safety and Compliance

Safety and compliance certifications play a critical role in ensuring that power distribution equipment meets international standards. These certifications protect both equipment and personnel, while also supporting regulatory compliance in global markets.

International Certifications (GS, CE, VDE, UL, BS, CB, ROHS, CCC)

A wide range of certifications validate the safety, environmental responsibility, and performance of power distribution equipment. The table below highlights the most important certifications and their impact:

| Certification | Region/Scope | Impact on Product Quality and Safety |

|---|---|---|

| ISO9001 | International | Ensures consistent manufacturing quality and process control |

| UL Listed | North America | Guarantees safety from fire, electric shock, and hazards |

| CE Mark | European Union | Confirms compliance with EU safety and low-voltage directives |

| RoHS Compliance | EU and others | Restricts hazardous substances, promoting environmental safety |

| VDE | Germany/Europe | Validates electrical safety and performance standards |

| IEC CB Scheme | International | Harmonizes safety standards for global acceptance |

| FCC Compliance | United States | Limits electromagnetic emissions for device compatibility and safety |

| UKCA Mark | Great Britain | Ensures product compliance with local regulations |

These certifications ensure that products meet the highest standards for electrical safety, environmental protection, and operational reliability.

Choosing Trusted Manufacturers Like YOSUN

Selecting a trusted manufacturer remains essential for long-term performance and safety. YOSUN, with over 20 years of experience, exemplifies this commitment. The company’s products hold multiple international certifications, including GS, CE, VDE, UL, BS, CB, ROHS, and CCC. YOSUN’s dedication to quality and compliance ensures that each solution meets the evolving needs of modern IT infrastructure. Customers benefit from robust, customizable products that deliver reliable power management and peace of mind.

Real-World Benefits and Case Examples of PDU Power Strips

Downtime Prevention in Action

Case Study: Avoiding Data Center Outages with Redundant PDU Power Strips

Organizations that operate mission-critical data centers often face the risk of costly outages. By deploying redundant power distribution solutions, they achieve higher reliability and operational continuity. For example, law firms like Duane Morris LLP implemented intelligent PDUs across multiple offices. Their IT teams gained the ability to remotely power cycle servers and network devices, which eliminated the need for emergency onsite visits. Real-time monitoring at both the PDU and outlet level allowed staff to detect anomalies early and manage power proactively. The system’s alerting features provided timely notifications about UPS battery runtime and environmental changes, such as temperature or humidity spikes. As a result, the frequency of unplanned outages and after-hours interventions dropped significantly.

- Remote reboot capability for unresponsive devices, such as VoIP switches, reduced downtime.

- Centralized management enabled global oversight from a single console.

- Security features, including encryption and access controls, ensured safe remote operations.

- Environmental sensors provided alerts on temperature, humidity, and physical access.

These measures collectively improved operational efficiency and gave IT staff greater peace of mind.

Case Study: Enhancing Remote Power Management with Intelligent PDU Power Strips

Intelligent PDUs have transformed remote power management for many organizations. Companies now monitor power draw in real time and receive alerts when thresholds are exceeded. This proactive approach prevents overloads and supports rapid response to issues. Centralized software platforms allow IT teams to manage all PDUs globally, streamlining maintenance and firmware updates. Environmental sensors integrated with the system further enhance reliability by providing early warnings about potential hazards. These capabilities have led to fewer onsite visits, reduced emergency calls, and improved uptime.

Cost Savings and Efficiency Gains

Reduced Maintenance Costs with Smart Monitoring

Smart monitoring features deliver measurable cost savings. Intelligent PDUs provide real-time energy consumption data, helping organizations identify inefficiencies and prevent overloads. Remote management capabilities allow IT teams to power down unused devices, which reduces electricity bills and extends equipment lifespan. Environmental monitoring lowers risks such as overheating, while energy-saving modes and intelligent load balancing further reduce operational costs. Advanced reporting and predictive analytics support strategic planning and capacity management.

| Reported Improvement | Quantifiable Gain | Description of Benefit |

|---|---|---|

| Energy Savings | Up to 30% reduction in energy costs | Real-time monitoring and remote management enable powering down unused equipment, reducing electricity bills. |

| Downtime Reduction | 25% less unplanned downtime | Remote management and proactive maintenance minimize downtime and improve system reliability. |

| Operational Efficiency | Enhanced through remote monitoring | Features like load balancing, environmental sensing, and outlet-level tracking optimize resource use. |

| Cost Savings | Long-term reduction in operational costs | Energy-saving modes and predictive analytics support strategic planning and reduce labor costs. |

Improved Uptime Metrics in Professional IT Environments

Advanced PDUs deliver significant improvements in uptime and reliability. Managed power distribution optimizes energy use and prevents overloads. Remote monitoring and outlet-level control enable faster issue resolution, while load balancing extends equipment lifespan. Environmental sensors provide early alerts, helping maintain optimal conditions and reducing downtime. Redundancy features, such as dual power inputs and automatic transfer switching, eliminate single points of failure. Organizations report up to 99.99% uptime and substantial reductions in maintenance response times. These benefits support business continuity and protect valuable IT assets.

A PDU power strip remains essential for reliable and manageable power in any server room. IT managers should focus on build quality, advanced features, and compatibility when selecting a solution. The table below highlights key considerations:

| Key Takeaway | Explanation |

|---|---|

| Build Quality and Durability | Use robust materials for long-term reliability. |

| Advanced Features | Choose PDUs with monitoring and remote management. |

| Surge and Overload Protection | Ensure strong safeguards for critical equipment. |

| Compatibility | Match rack size and plug types for seamless integration. |

Smart PDUs with real-time monitoring and remote control help reduce downtime and operational costs. Regular maintenance and proper sizing further support continuous operation and peace of mind.

FAQ

What is the main difference between a PDU power strip and a regular power strip?

A PDU power strip distributes power safely to multiple devices in high-demand environments. It supports higher loads, offers advanced monitoring, and includes features like surge protection and remote management. Regular power strips lack these capabilities and suit less critical applications.

How does a PDU power strip help prevent server room downtime?

A PDU power strip balances electrical loads, monitors power usage, and provides surge and overload protection. These features reduce the risk of outages and equipment failure, ensuring continuous operation for critical IT infrastructure.

Can a PDU power strip be customized for specific server room needs?

Yes. YOSUN offers customizable PDUs with options for outlet type, quantity, mounting style, voltage, and current ratings. Customers can select features like remote monitoring, environmental sensors, and enclosure materials to match their unique requirements.

What certifications should a quality PDU power strip have?

A quality PDU power strip should carry certifications such as UL, CE, GS, VDE, CB, ROHS, and CCC. These certifications ensure safety, reliability, and compliance with international standards.

Tip: Always verify certifications before purchasing to guarantee product safety.

How often should technicians inspect and maintain PDU power strips?

Technicians should perform visual inspections and maintenance every three to six months. High-traffic or dusty environments may require more frequent checks. Regular testing ensures reliable performance and extends equipment lifespan.

Can a PDU power strip support remote monitoring and control?

Intelligent PDUs support remote monitoring and control through network connectivity. Operators can track power usage, receive alerts, and manage outlets from anywhere, improving response times and operational efficiency.

What safety features do YOSUN PDU power strips include?

YOSUN PDU power strips feature built-in circuit breakers, surge protection, overload prevention, and heat-resistant materials. Some models offer weatherproof and shockproof designs for harsh environments.

| Safety Feature | Benefit |

|---|---|

| Circuit Breakers | Prevents overload damage |

| Surge Protection | Shields against voltage spikes |

| Heat Resistance | Withstands high temperatures |

Are PDU power strips suitable for future server room expansion?

Yes. PDUs with modular designs and scalable outlet configurations support future growth. YOSUN’s customizable options allow organizations to plan for additional equipment and evolving power needs.

Post time: Jul-24-2025