Power problems cause over half of all data center outages. ATS PDU solutions respond in milliseconds, switching to backup power before systems notice any loss.

This rapid action protects equipment and keeps operations running smoothly.

The table below shows how fast switching and redundancy make a difference:

| Aspect | Details |

|---|---|

| Percentage of outages caused by power failures | Over 50% of data center outages stem from power problems including electrical system failures, human error, UPS and generator failures, and cooling system failures. |

| Impact of ATS PDUs | Dual input PDUs with automatic transfer switching reduce downtime by 25% or more by providing redundancy and fast switching between power sources, preventing interruptions. |

| Additional benefits | Increased uptime, protection from power surges, energy savings up to 20%, and improved equipment protection. |

Key Takeaways

- ATS PDUs automatically switch power between two sources in milliseconds, preventing downtime in data centers.

- These units provide redundancy and protect equipment from power surges, fluctuations, and outages.

- Real-time monitoring and remote management help detect issues early and improve maintenance response.

- Proper installation and regular testing ensure reliable operation and maximize uptime.

- ATS PDUs integrate with UPS, generators, and DCIM tools to create a strong, flexible power system.

- Load balancing and energy efficiency features reduce power waste and support green data center goals.

- Advanced technologies like AI and smart analytics enable predictive maintenance and faster problem detection.

- Following best practices and using certified ATS PDUs help data centers meet strict uptime and safety standards.

ATS PDU: Definition and Core Function

What Is an ATS PDU?

An ATS PDU, or Automatic Transfer Switch Power Distribution Unit, is a specialized device that ensures continuous power delivery to critical equipment. This unit connects to two separate power sources, such as utility power and a backup generator. When the primary source fails or becomes unstable, the ATS PDU automatically switches to the secondary source. This process happens without manual intervention, keeping servers and network devices running smoothly.

Industry standards recognize Metered Auto Transfer Switch PDUs and Switched Auto Transfer Switch PDUs for their ability to enhance power reliability. These units provide unfiltered power pass-through to single-corded equipment and monitor input and output voltage and amperage. The ATS PDU acts as an intermediary between electrical equipment and power sources, ensuring that power interruptions do not impact operations. Regular monitoring and maintenance help maintain reliability, especially in environments with high energy loads.

How ATS PDU Integrates with Data Center Infrastructure

Data centers rely on ATS PDUs to maintain uptime and protect sensitive equipment. These units fit into standard racks and connect directly to both primary and backup power sources. The integration of ATS PDUs with uninterruptible power supplies (UPS) and backup generators creates a robust power chain. When the main power source fails, the ATS PDU instantly switches to the backup, preventing downtime.

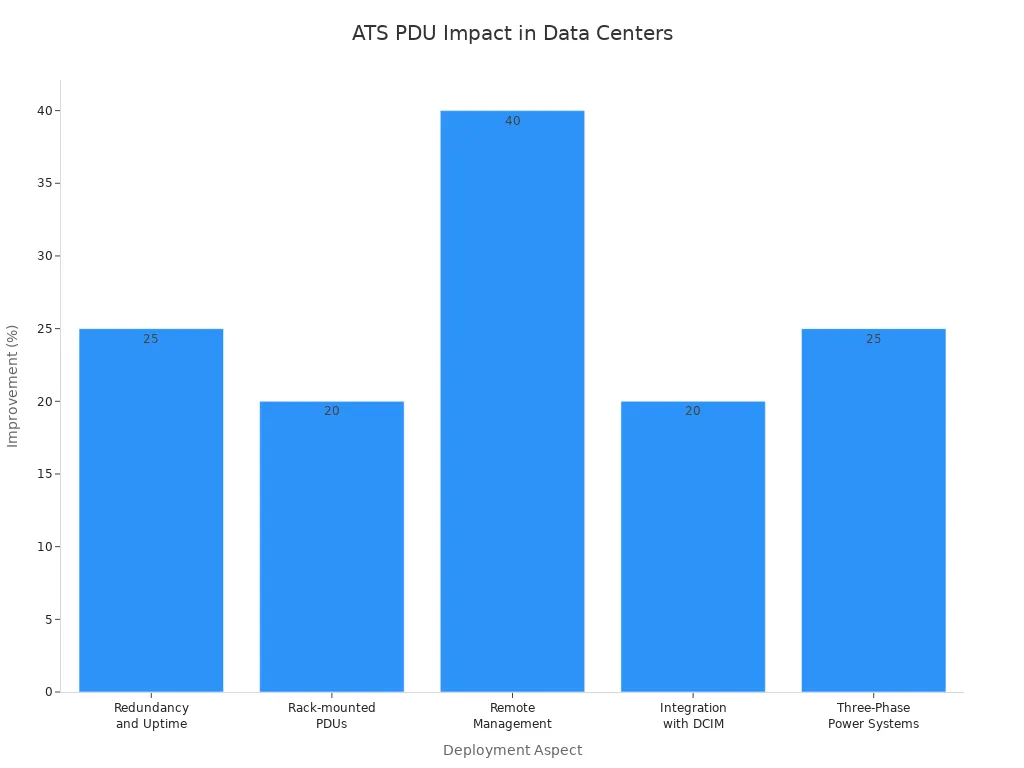

The following table highlights how ATS PDUs support data center operations:

| Aspect | Description | Impact |

|---|---|---|

| Redundancy and Uptime | Switches to alternate power sources automatically. | Increases reliability by 25% in backup-configured facilities. |

| Integration with UPS | Works with UPS to deliver uninterrupted power. | Critical for high-uptime environments. |

| Rack-mounted PDUs | Installs in racks for optimized power management and surge protection. | Reduces energy waste by up to 20%; avoids costly downtime. |

| Remote Management | Enables remote control and monitoring of power outlets. | Improves maintenance response times by 40%. |

| Integration with DCIM | Provides real-time power and environmental metrics for better planning. | Improves power efficiency by 20%; saves 10-15% on cooling costs. |

| Three-Phase Power Systems | Supports higher power density and improved load balancing. | Boosts operational performance by 25%; supports over 22 kW per rack PDU. |

| Scalability and Flexibility | Designed for easy expansion as infrastructure grows. | Enables seamless expansion and reduces long-term costs. |

| Edge and Remote Data Centers | Supports remote management, reducing the need for on-site personnel. | Enhances flexibility and saves costs in distributed environments. |

Key Components of ATS PDU

The ATS PDU contains several essential components that work together to deliver seamless power switching:

- Dual Power Interfaces: Connects to both primary and backup power sources, such as utility lines and generators.

- Sensors and Monitoring Equipment: Continuously checks voltage, frequency, and phase to detect any power issues.

- Mechanical or Semiconductor Switch: Transfers power between sources quickly and safely.

- Control Logic: Uses a microprocessor to monitor power status and trigger switching operations.

- Enclosure and Mechanical Structure: Protects internal parts and ensures operator safety.

- Manual Control Panel: Allows for manual operation and maintenance when needed.

The control logic inside the ATS PDU monitors both power sources at all times. If it detects a problem with the primary source, it switches to the backup source automatically. When the primary source stabilizes, the system returns the load to it. This intelligent automation ensures that data center equipment receives reliable power without interruption.

Seamless Power Switching Mechanisms in ATS PDU

Automatic Monitoring and Detection

Real-Time Voltage and Frequency Sensing

ATS PDUs use advanced sensors and built-in intelligence to monitor both primary and secondary power sources at all times. These sensors check voltage, frequency, and power stability. The system tracks these values in real time, making sure that the power supply meets strict standards. If the voltage or frequency drops below safe levels, the ATS PDU prepares to switch to the backup source. This constant monitoring helps prevent sudden power loss and keeps equipment safe.

- The ATS PDU checks voltage and frequency for both power sources continuously.

- It uses real-time data to detect failures or drops below set thresholds.

- The system avoids unnecessary switching by making decisions based on accurate readings.

- Many models allow users to track power usage and load levels in real time.

- Users can set which power source is primary or secondary and monitor the system remotely.

Identifying Power Anomalies

The ATS PDU identifies power anomalies by analyzing the data from its sensors. It looks for signs of instability, such as sudden voltage spikes, frequency changes, or power interruptions. When the system detects a problem, it triggers an automatic transfer to the backup source. This process happens quickly, often before users notice any issue. The ATS PDU also sends alerts to users about detected anomalies, allowing for fast response and maintenance.

Note: Real-time detection and alerting help data center teams respond to power issues before they cause downtime.

Rapid Transfer Technology

Millisecond-Level Switching

The ATS PDU uses rapid transfer technology to switch between power sources in just a few milliseconds. Mechanical switching mechanisms can achieve transfer times between 10 to 16 milliseconds. Solid-state devices, such as Silicon Controlled Rectifiers (SCRs) and Insulated Gate Bipolar Transistors (IGBTs), enable even faster switching—often less than 4 milliseconds. These technologies ensure that connected equipment continues to receive power without interruption.

CyberPower’s ATS PDU models, for example, specify total transfer times of less than 10 milliseconds. This includes both the time needed to detect a source failure and the time to complete the transfer. Such fast response times are critical for sensitive data center equipment.

Minimizing Power Interruption

By switching power sources within milliseconds, the ATS PDU minimizes the risk of power interruption. Servers, storage devices, and network equipment remain powered and operational, even during utility failures or generator startups. The seamless transition protects against data loss and system crashes. Data centers can rely on this technology to maintain high availability and meet strict uptime requirements.

Protection Against Power Issues

Overload and Surge Protection

The ATS PDU provides multiple layers of protection for data center equipment. It allows devices with a single power supply to draw power from two sources, similar to dual power supply servers. Users can set the priority between sources, choosing the best quality power, such as a pure sine wave from a UPS. The system offers redundancy for single-corded devices, improving reliability and reducing the risk of power loss.

- Dual power cords connect to separate sources for continuous power.

- Only compatible sine wave AC sources are allowed, preventing waveform issues.

- Remote and local monitoring help track power status and detect problems early.

- Automatic notifications alert users to events like surges or overloads.

- The design prevents accidental shutdowns and protects internal components.

Isolation of Faulty Power Sources

When the ATS PDU detects a faulty power source, it isolates that source and switches to the backup. This automatic switching prevents downtime caused by outages or unstable power. The system works with UPS units and generators to provide flexible redundancy. UPS systems condition the power, protecting against surges and spikes. Generators serve as backup sources, with the ATS PDU transferring the load as needed. This combination shields sensitive equipment from power interruptions and electrical disturbances.

Tip: Using an ATS PDU with both UPS and generator power creates a strong defense against power problems in any data center.

Benefits of ATS PDU for Data Centers

Maximizing Uptime and Availability

Continuous Power Delivery

Data centers depend on uninterrupted power to keep servers and applications running. ATS PDUs play a vital role by connecting to two independent power sources. This setup ensures that if one source fails, the system instantly switches to the backup. Operations continue without interruption, which is essential for mission-critical environments.

- Dual input PDUs provide redundancy by accepting power from two sources.

- Seamless switching between sources happens automatically, reducing downtime.

- Load balancing distributes power evenly, preventing overloads.

- Real-time monitoring and remote management allow teams to detect issues early.

- Combining two PDUs into one chassis saves rack space and simplifies cabling.

- Integration with backup generators increases resilience during power disruptions.

Reliable power delivery keeps data centers online, even during unexpected outages.

Reducing Outage Risks

ATS PDUs reduce the risk of outages by automating the switch between primary and secondary power sources. This automation removes the chance of human error and allows maintenance without stopping operations. Redundant power infrastructure protects against surges and outages, lowering the risk of equipment damage.

- Automatic switching ensures continuous power supply.

- Redundancy protects against complete power loss.

- Real-time monitoring enables proactive management.

- Integration with generators supports automatic power restoration.

- Remote management improves operational control and energy efficiency.

Equipment Protection and Longevity

Preventing Damage from Power Fluctuations

Power fluctuations can harm sensitive equipment. ATS PDUs protect devices by switching to stable power sources when they detect voltage drops or surges. This feature shields hardware from sudden changes that could cause failures.

Extending Equipment Lifespan

Regular maintenance and testing of ATS PDUs help identify issues early. This practice reduces downtime and prevents equipment failure. Environmental monitoring, such as temperature and humidity checks, also supports optimal conditions. These actions extend the lifespan of data center equipment and maintain efficient operations.

- Automatic switching prevents downtime and damage.

- Environmental monitoring helps avoid overheating.

- Redundant power and remote management keep equipment powered during disruptions.

Supporting Operational Continuity

Maintaining Critical Applications

Continuous power delivery ensures that critical applications remain available. ATS PDUs support this by switching to backup sources instantly, keeping essential services online.

Meeting Service Level Agreements (SLAs)

Data centers must meet strict SLAs for uptime. ATS PDUs help achieve these goals by providing reliable power from redundant sources and switching automatically when needed. Real-time monitoring allows quick responses to power issues, supporting uptime targets like 99.999% availability.

Consistent power supply and proactive management help data centers meet demanding SLA requirements.

Reliability Features of ATS PDU

Redundant Power Inputs and Failover

Dual Power Source Capability

Data centers require continuous power to support critical operations. ATS PDUs deliver this reliability by connecting to two independent power sources. This dual input design eliminates single points of failure. If one source experiences a problem, the other source keeps equipment running. Many facilities use a combination of utility power and a backup generator or UPS system. This flexible configuration supports different power needs and ensures that essential systems always have access to electricity.

Failover Support

Failover mechanisms in ATS PDUs monitor both power sources at all times. When the primary source fails, the unit automatically switches to the backup within milliseconds. This seamless transition happens without manual intervention, reducing downtime and protecting sensitive equipment. Regular testing of failover systems, including simulated power failures, helps ensure that the system responds correctly during real emergencies. These features work together to maximize uptime and minimize the risk of service interruptions.

Tip: Regularly test failover functions to confirm that the system will respond as expected during a real outage.

Intelligent Monitoring and Alerts

Remote Status Monitoring

Modern ATS PDUs include intelligent monitoring features. These units track power consumption in real time at both the outlet and branch circuit levels. Environmental sensors monitor temperature, humidity, and airflow. This data helps IT teams detect issues early and maintain optimal conditions for equipment. Remote management tools allow administrators to check the status of the PDU from anywhere, improving response times and reducing the need for on-site visits.

Automated Notifications

Automated alerts play a key role in maintaining reliability. The system sends notifications when it detects power anomalies, environmental risks, or unusual consumption patterns. Customizable thresholds let teams set specific alert levels for voltage, temperature, or humidity. Early warnings help prevent downtime and support disaster recovery plans. Integration with data center management tools allows for centralized control and faster decision-making.

Build Quality and Compliance

Industrial-Grade Components

ATS PDUs use industrial-grade components to withstand demanding data center environments. Surge protection absorbs voltage spikes, shielding sensitive equipment from damage. The robust construction ensures long-term durability and reliable performance, even under heavy loads.

Certification and Standards

Compliance with international standards is essential for data center safety. Many ATS PDUs meet certifications such as UL Listed, CE Mark, FCC Class A, and IEC 62368-1. These certifications confirm that the units have passed rigorous tests for electrical safety, fire protection, and electromagnetic compatibility. The table below highlights some common certifications and their importance:

| Certification/Standard | Importance for Data Center Compliance |

|---|---|

| UL Listed | Ensures fire and electrical safety |

| CE Mark | Confirms EU safety compliance |

| FCC Class A | Controls electromagnetic emissions |

| IEC 62368-1 | Meets up-to-date safety standards |

Meeting these standards helps protect equipment, maintain continuous operations, and support compliance with global regulations.

Best Practices for ATS PDU Deployment

Installation and Setup Guidelines

Location and Rack Compatibility

Proper installation of power distribution units starts with careful planning. Data center teams should position PDUs for easy access, avoiding blockage of other equipment. Vertical or horizontal mounting helps optimize cable management and reduces clutter. Teams must ensure that PDUs do not obstruct airflow, which supports effective heat dissipation. Keeping units within arm’s reach allows for straightforward maintenance and monitoring. Maintaining minimum clearances, such as 1200mm at the front, improves safety and accessibility. The following checklist summarizes key steps:

- Place PDUs for accessibility and safety.

- Use mounting options that fit the rack layout.

- Avoid blocking airflow to maintain cooling efficiency.

- Keep units within reach for maintenance.

- Balance loads across PDUs to prevent overloading.

- Follow manufacturer and industry guidelines.

- Confirm outlet compatibility and load ratings.

- Ensure all connections meet electrical codes.

Tip: Certified personnel should handle installation and maintenance, following safety standards like EN50110-1 2013.

Connecting to Independent Power Sources

Connecting each PDU to independent power sources increases redundancy. Teams should power A- and B-feed rack PDUs from separate panels. Single power supply servers can draw from the rack ATS, which connects to one of the rack PDUs. This approach supports accurate inventory and reporting, while enabling power dependency and impact simulation. Teams must verify secure electrical connections, especially for protective earth cables, and perform insulation resistance tests to prevent short circuits.

Regular Maintenance and Testing

Scheduled Inspections

Routine inspections help maintain system reliability. Annual checks of the ATS, including timing functions and contact testing, are recommended for critical loads. Teams should also run generators monthly without load and every six months under load. UPS or DC plant batteries require testing every six months and replacement every four years. Regular testing ensures the backup power system operates as intended.

Functional Testing Procedures

Testing procedures should include utility failure simulations to confirm automatic switching. Teams must use pre-start checklists and follow five safety rules: disconnect, prohibit re-connection, secure installation, earth and short, and shroud live components. These steps help prevent accidents and ensure the ATS PDU functions correctly during real outages.

Leveraging Remote Management

Centralized Control Platforms

Remote management platforms allow IT teams to monitor and control power distribution from any location. These systems enable real-time monitoring, power cycling of unresponsive equipment, and remote shutdown of unused outlets. Centralized control reduces the need for physical inspections, saving time and operational costs.

Real-Time Data Analytics

Real-time analytics provide insights into power usage, load balancing, and capacity planning. Alerts notify teams of potential issues, allowing for proactive responses before problems escalate. Integration with existing systems through multiple communication protocols ensures seamless management. Data analytics tools support trend analysis and help identify high energy-consuming equipment, supporting sustainability goals.

Note: Remote management and analytics can reduce mean time to resolve hardware outages by over 20% and help avoid several incidents each year.

Addressing Challenges with ATS PDU

Compatibility and Integration

Matching ATS PDU Specifications to Equipment

Data centers often face compatibility challenges when deploying new power distribution units. Operators must ensure that the ATS PDU matches the technical requirements of existing equipment. Common issues include differences in communication protocols, plug and outlet types, and voltage or current ratings. Integration with legacy management platforms can also present obstacles. To avoid these problems, operators should:

- Confirm support for required communication protocols, such as SNMP or HTTP.

- Match plug and outlet types to the equipment already in use.

- Check voltage and current ratings for all devices.

- Review integration options with current management software.

Careful planning and consultation with vendors help prevent compatibility problems. Consistent quality standards across all components ensure reliable power delivery and avoid power quality issues.

Ensuring Proper Installation

Proper installation is essential for reliable operation. Technicians should follow manufacturer guidelines and industry best practices. Secure electrical connections and correct grounding protect both equipment and personnel. Custom adapters or software modifications may be necessary for some setups. Teams should test the system after installation to verify seamless switching and integration with monitoring platforms.

Load Balancing and Power Distribution

Avoiding Overloads

Load balancing plays a key role in preventing overloads. Data centers distribute electrical loads evenly across connected equipment. This practice helps avoid overloading generators linked through the ATS PDU and reduces the risk of power outages. Redundancy, achieved by using multiple ATS units and backup generators, ensures that power remains available even if one component fails.

Optimizing Power Allocation

Regular maintenance and testing of ATS devices help detect faults early. Remote monitoring enables technicians to identify potential issues before they cause downtime. Personnel training ensures that staff can operate and maintain ATS systems effectively. These steps support optimal power allocation and maintain system reliability.

Tip: Regularly review load distribution and perform scheduled maintenance to keep the power system running smoothly.

Responding to Power Source Failures

Automated Recovery Protocols

In mission-critical environments, ATS PDUs provide rapid automatic switching to backup power sources. Devices with single power supplies connect to two separate UPS systems through the ATS unit. When one UPS fails, the ATS PDU switches power to the secondary UPS, ensuring no downtime for connected equipment. Advanced monitoring and alarm functions notify staff of temperature changes, voltage interruptions, or device responsiveness issues. Configurable notifications and event logging help teams diagnose and resolve problems quickly.

Manual Override Options

Manual override options allow technicians to switch power sources during maintenance or emergencies. This feature ensures continuous uptime and operational reliability. Security measures, such as password protection and authentication protocols, safeguard access to configuration and commands. These protocols enable proactive management of power redundancy and support uninterrupted operations in data centers.

Future Trends in ATS PDU Technology

Advancements in Smart Monitoring

AI-Driven Predictive Maintenance

Data centers now use artificial intelligence to keep equipment running smoothly. AI-driven predictive maintenance uses real-time sensor data, such as power, temperature, and humidity, to spot problems before they cause failures. Machine learning models, including random forest and neural networks, analyze patterns and predict when maintenance is needed. Digital twin technology creates a virtual copy of the system, helping teams detect faults and plan repairs early. These smart systems connect with cloud-based monitoring tools, allowing remote control and fast response to issues. As a result, data centers reduce downtime and lower maintenance costs.

- AI and machine learning help predict failures before they happen.

- Digital twins use real-time data to improve fault detection.

- Cloud integration supports remote monitoring and early alerts.

Enhanced Data Analytics

Modern ATS PDUs collect large amounts of data from sensors. Enhanced analytics tools process this information to find trends and improve performance. Operators use these insights to balance loads, prevent overloads, and optimize energy use. Real-time dashboards show power usage and environmental conditions, making it easier to spot problems. These analytics help data centers make better decisions and keep systems running efficiently.

Integration with Data Center Automation

Orchestration with DCIM Tools

Data center infrastructure management (DCIM) tools now work closely with ATS PDUs. This integration allows teams to monitor power, cooling, and equipment status from a single platform. Automated workflows help manage power events, such as switching sources or balancing loads. Operators can set rules for automatic actions, reducing the need for manual intervention.

Automated Response to Power Events

Automation helps data centers respond quickly to power changes. When a power event occurs, the system can switch sources, send alerts, and adjust loads automatically. This fast response protects equipment and keeps services online. Automated systems also log events for future analysis, supporting continuous improvement.

Sustainability and Energy Efficiency

Reducing Power Waste

Intelligent rack PDUs, including ATS PDU models, help reduce energy waste by up to 20%. They use real-time monitoring, load balancing, and remote outlet control to optimize power use. These features ensure that only necessary equipment receives power, cutting down on waste and saving money.

| Benefit | Improvement | Source Type |

|---|---|---|

| Reliability with ATS PDUs | 25% increase | Industry benchmark |

| Energy waste reduction | Up to 20% | Industry study |

| Power efficiency via load balancing | 20% increase | Industry intelligence |

Supporting Green Data Center Initiatives

Sustainability is a top goal for modern data centers. ATS PDUs support green initiatives by enabling real-time energy monitoring and load balancing. These features help operators use less energy and lower CO₂ emissions. High-efficiency transformers and remote management tools allow teams to power down idle equipment, further reducing consumption. Companies like Target and eBay have saved energy and cut costs by using these technologies. As data centers grow, these solutions will play a key role in meeting environmental goals.

Data centers rely on ATS PDU technology to keep critical systems running without interruption. These units automatically switch between power sources, reducing downtime and protecting valuable equipment. Operators benefit from real-time monitoring, remote management, and intelligent power distribution. By following best practices and using advanced features, teams can maximize uptime, prevent overloads, and ensure smooth operations. Reliable power management supports continuous service and helps avoid costly disruptions.

FAQ

What does ATS stand for in ATS PDU?

ATS stands for Automatic Transfer Switch. This feature allows the PDU to switch between two power sources automatically, ensuring continuous power for critical equipment.

How fast does a YOSUN ATS PDU switch power sources?

YOSUN ATS PDUs typically switch between power sources within 2 to 5 milliseconds. This rapid response keeps connected devices running without interruption.

Can ATS PDUs protect single-corded devices?

Yes. ATS PDUs provide redundancy for single-corded devices by connecting them to two independent power sources. This setup increases reliability and reduces the risk of downtime.

What types of power sources can connect to an ATS PDU?

An ATS PDU connects to two separate power sources, such as utility power and a backup generator or UPS. This dual connection ensures reliable power delivery.

Is remote monitoring available with YOSUN ATS PDUs?

Many YOSUN ATS PDUs offer remote monitoring features. Users can track power usage, receive alerts, and manage settings from a centralized platform.

How often should data centers test their ATS PDUs?

Data centers should schedule regular inspections and functional tests at least once a year. Routine testing helps ensure the ATS PDU operates correctly during real power events.

Are YOSUN ATS PDUs certified for safety and quality?

YOSUN ATS PDUs meet international standards, including GS, CE, ULBS, and ROHS. These certifications confirm the units’ safety, reliability, and compliance with industry requirements.

Post time: Jul-24-2025