I believe intelligent OEM rack PDUs are vital. They optimize power distribution, offering granular control and real-time monitoring at the rack. These solutions provide critical insights beyond basic power strips. Over 60% of data centers use intelligent PDUs, boosting efficiency and uptime. I see them as key for modern IT.

Key Takeaways

- Intelligent OEM rack PDUs give you full control over power in your server racks. They let you watch power use, turn outlets on or off, and reboot devices from far away.

- These smart PDUs help save money and energy. They show you where power is wasted, so you can make changes to use less electricity.

- Intelligent PDUs make your computer systems more reliable. They warn you about problems before they happen, which keeps your equipment running and prevents shutdowns.

Understanding Intelligent OEM Rack PDUs

Defining an Intelligent OEM Rack PDU

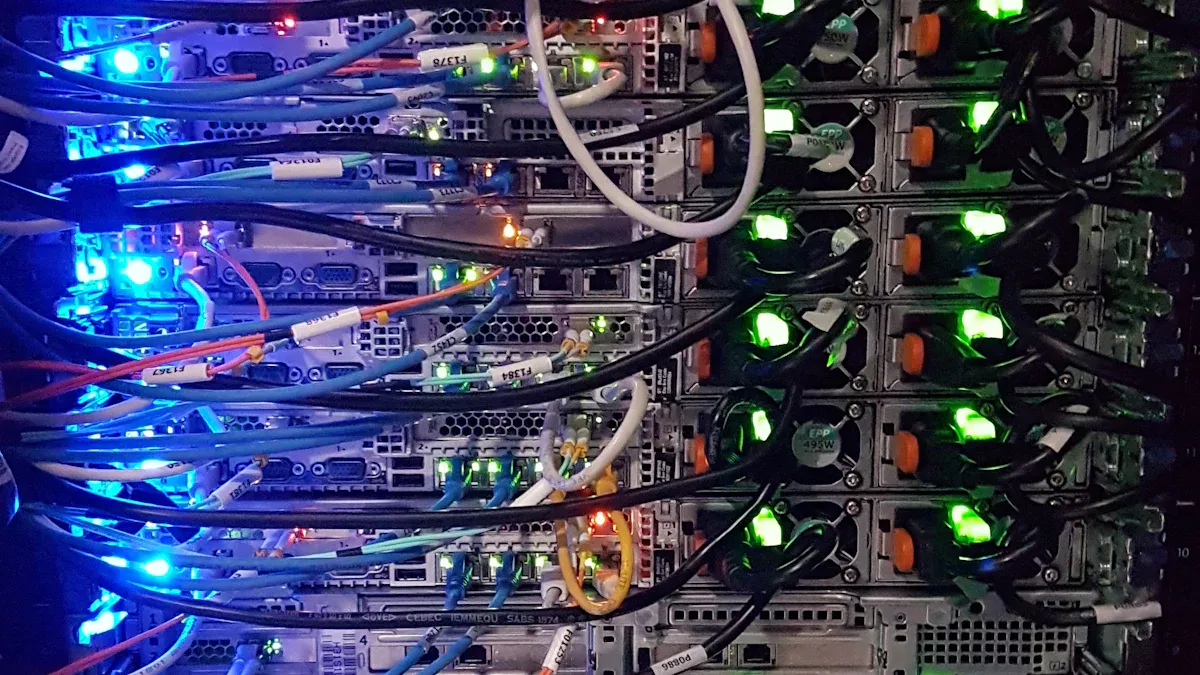

I see intelligent OEM rack PDUs as more than just basic power strips. They are smart devices that give you detailed control and monitoring over your power. They help you manage power usage right in your server racks. I find them crucial for modern data centers. These PDUs come in different types. Some are “monitored,” giving you a full view of power use at the rack or even individual outlets. This helps you track energy and improve efficiency. Others are “switched,” which means you can remotely turn outlets on or off, or even reboot equipment. This is super handy for remote sites or preventing overloads.

Key Components of an OEM Rack PDU

When I look at an intelligent OEM rack PDU, I notice several key parts. Many have flexible outlets like HDOT Cx, which can take both C14 and C20 plugs. This makes them versatile. I also see RamLock locking outlets that keep cables secure, preventing accidental unplugging. For environmental insights, SmartSensors are often integrated. These plug-and-play devices monitor things like temperature and humidity right in the rack. The core intelligence often comes from a platform like the Xerus Technology Platform. This combines hardware and software to give you strong security, high processing power, and clear visibility into your power. I also appreciate their “Future-Proof Design,” allowing for easy upgrades of monitoring devices without replacing the whole unit. This means I can adapt to new tech without downtime.

OEM vs. Standard Rack PDU Solutions

Now, let’s talk about how an intelligent OEM rack PDU differs from a standard one. It’s a big difference, really. A standard PDU just distributes power; it has no monitoring or control. But an intelligent PDU does so much more.

| Feature | Standard PDU | Intelligent PDU |

|---|---|---|

| Monitoring | No monitoring capabilities. | Monitors power consumption at rack, outlet, or device level. |

| Control | No remote control over power. | Remotely controls individual outlets (on/off/reboot). |

| Metering | No metering. | Provides real-time power metering (current, voltage, power factor, etc.). |

| Alerts & Notifications | No alerts. | Sends alerts for power overloads, circuit breaker trips, or environmental issues. |

| Networking | No network connectivity. | Network connectivity (Ethernet, serial) for remote access and management. |

| Cost | Lower initial cost. | Higher initial cost due to advanced features. |

| Use Case | Simple power distribution in non-critical environments. | Critical IT infrastructure, data centers, and remote sites requiring advanced power management. |

I also find that intelligent PDUs offer IP Aggregation, which lets multiple PDUs share one IP address, saving costs. They also provide remote connectivity and can integrate with DCIM solutions for a single view of all data. This makes managing my infrastructure much easier.

Why Intelligent OEM Rack PDUs are Essential for Power Optimization

Enhanced Power Monitoring and Analytics with OEM Rack PDUs

I find that one of the biggest advantages of an intelligent OEM rack PDU is its ability to give me a deep look into my power usage. They don’t just tell me if power is on or off. Instead, they monitor a lot of specific data points. For example, I can track:

- Voltage: This shows me if the power supply is stable. I can catch undervoltage or overvoltage conditions before they cause problems.

- Current: I can see load levels in real time. This helps me avoid overloads and keep circuits balanced.

- Active Power (kW): This tells me the actual energy my devices are using.

- Apparent Power (kVA): This reflects the total power drawn. It helps me plan capacity accurately.

- Reactive Power (kVAr): This can point out inefficiencies from certain types of loads.

- Power Factor (PF): I use this to evaluate energy efficiency and optimize power usage.

Beyond these, I can also monitor for things like total harmonic distortion events, voltage dips and swells, crest factor, and even power interruptions. This real-time monitoring lets me see power usage metrics right at the unit level. I can use this data for load balancing, making sure power is spread evenly. If power usage gets too high, I get threshold alerts. This helps me prevent issues. All these insights help me track consumption trends and find ways to save energy.

Advanced analytics from these PDUs really help me find power inefficiencies. I can pinpoint specific outlets causing problems. I can even capture waveform data for deeper analysis. Remote monitoring of power conditions is a game-changer. These tools offer advanced power quality monitoring and measurements. This helps me troubleshoot issues proactively and optimize my PUE (Power Usage Effectiveness) and CUE (Carbon Usage Effectiveness). I also get Total Harmonic Distortion monitoring to measure electrical load distortion. Plus, Circuit Breaker Trip Forensics helps me identify exactly which outlet and device caused a trip.

Granular Power Control and Switching Capabilities

I love the control intelligent PDUs give me. It’s not just about monitoring; it’s about taking action. I can manage power right down to individual outlets.

- Remote Individual Outlet Switching: With switched PDUs, I can turn individual outlets on or off from anywhere. This gives me precise control over power to specific devices.

- Remote Power Cycling: If a piece of equipment freezes up, I can remotely power cycle it. This means I can reboot unresponsive gear without having to go to the data center. It really cuts down on downtime.

- Scheduled Shutdowns: I can even schedule shutdowns for equipment that isn’t being used. This is a great way to cut down on wasted energy.

Managed PDUs take this a step further. They offer remote rebooting of devices, which means I don’t need to be physically present. This is perfect for unmanned or remote data centers. I can switch individual outlets on or off to power down unused equipment. I can manage power to specific devices without affecting others. Managed PDUs combine detailed power insights with remote control. They give me granular power consumption data at the outlet level and let me switch individual outlets. I can monitor power draw and remotely cycle power to specific equipment. It’s all about having that control at my fingertips.

Proactive Anomaly Detection and Alerting

Intelligent PDUs are like having a watchful guardian for my power. They use smart analytics to look at power draw patterns. This helps them find weird things, like unusual spikes that might mean hardware is failing. This capability is amazing for predictive maintenance and finding anomalies early. It lets me step in before things goes wrong. Some models even use AI to guess when equipment might fail based on past power use. This helps me balance loads dynamically and avoid unexpected downtime. These systems also give me detailed insights at the outlet level. I can find inefficiencies like servers not being used enough or power loads that are out of balance.

Intelligent rack PDUs also give me remote access through web interfaces or special software. This means I can manage everything from one central spot. I can spot potential power problems early. This allows for proactive maintenance and really cuts down on downtime. I get real-time alerts and advanced monitoring. Switched PDUs are especially useful here. They let me control individual outlets remotely. I can turn devices on or off as needed, like rebooting a server without being there. This makes my operations more efficient and reduces downtime. I can detect common power anomalies such as crest factor, inrush current, harmonic distortion (including Total Harmonic Distortion – THD), phase imbalance, voltage dips, and even transients and swells. My response mechanisms include per-phase monitoring to rebalance loads and continuous power quality monitoring for predictive maintenance.

Improving Energy Efficiency and Cost Savings

I’ve seen firsthand how intelligent PDUs can make a big difference in energy efficiency and cost savings. The numbers really speak for themselves.

| Metric | Quantifiable Improvement/Saving |

|---|---|

| Energy Savings | Up to 20% |

| Reduced Downtime | 25% or more |

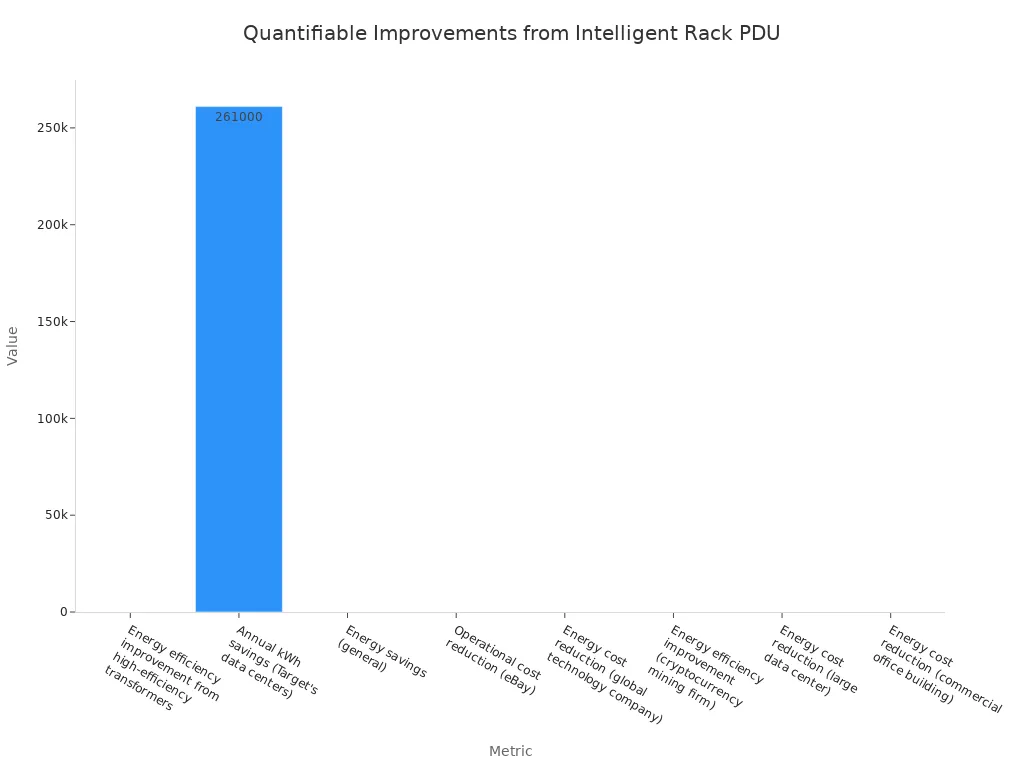

I’ve also seen data showing even more impressive results:

| Metric | Quantifiable Improvement/Saving |

|---|---|

| Energy efficiency improvement from high-efficiency transformers | 2% to 3% |

| Annual kWh savings (Target’s data centers) | 261,000 kWh |

| Energy savings (general) | Up to 20% |

| Operational cost reduction (eBay) | 50% |

| Energy cost reduction (global technology company) | 20% |

| Energy efficiency improvement (cryptocurrency mining firm) | 30% |

| Energy cost reduction (large data center) | 20% |

| Energy cost reduction (commercial office building) | 15% |

These savings come from being able to precisely monitor and control power. When I know exactly what’s using power, I can make smart decisions. I can turn off unused equipment or optimize loads. This leads to significant reductions in my energy bills.

The chart above clearly illustrates the various improvements and savings I can expect. It’s not just about saving a little; it’s about making a substantial impact on my operational budget.

Boosting Uptime and Reliability

I believe that keeping my IT infrastructure running smoothly is paramount. An intelligent OEM rack PDU plays a huge role in boosting uptime and reliability.

Callout: Investing in intelligent PDUs can reduce downtime costs and optimize energy usage, making them a smart choice for future-proof IT environments.

Intelligent PDUs offer advanced features like real-time monitoring and remote management. These are key for scaling my operations and keeping things efficient. They are much better than basic PDUs. Basic PDUs only distribute power. Intelligent PDUs give me:

- Real-time monitoring: I track power usage, voltage, and current. This helps me optimize energy and stop equipment from failing.

- Remote management: I can monitor and control PDUs from anywhere. I can cycle power at the outlet level or balance loads without being on-site.

- Proactive alerts: I set alarm thresholds. The system sends me notifications when power usage gets too high. This prevents circuit overloads and minimizes downtime.

- Scalability: These PDUs support high-density power designs. I can add more smart PDUs without stopping operations. This ensures my future growth.

Intelligent PDUs are perfect for high-density setups because they handle more power and offer advanced monitoring. Basic PDUs are only good for low-density environments. Intelligent PDUs track real-time power usage. They find inefficiencies and help me balance loads. This reduces energy waste and operational costs. I get precise energy metering accuracy, often within ±0.5%. This gives me reliable data for power management. I also get advanced power quality monitoring. This includes neutral voltage, total harmonic distortion, and voltage dip/swell metrics. I can see these at both the PDU inlet and outlets. This helps me find and prevent power quality issues. Circuit breaker trip forensics with waveform capture helps me figure out why a breaker tripped. This prevents future overloads. Environmental and security monitoring is also integrated. I can monitor airflow, temperature, and humidity in real time. This maximizes data center efficiency and protects my equipment from bad cooling.

Intelligent PDUs measure, manage, and report on energy usage in real-time. This lets me optimize energy consumption and handle equipment changes. I can remotely schedule power cycling for unused IT equipment. This reduces energy use. I can also proactively manage consumption for efficiency. Plus, intelligent PDUs give me proactive notifications for problems, like overload conditions. They send warnings and critical threshold alerts. This tells me to fix problems before they cause breaker trips and equipment failures. I get these notifications in standard ways, like SMS, SNMP traps, or email. I can also integrate intelligent PDUs with central management software for easier control.

Strategic Deployment of Intelligent OEM Rack PDUs

Assessing Current Power Needs and Infrastructure

Before I deploy any intelligent OEM rack PDU, I always start by looking closely at my current power setup. This step is super important. I evaluate my IT infrastructure first. This means I check the layout of my server racks. Do I need vertical or horizontal PDUs? I also identify all the device outlet types. Are they IEC C13, C19, or NEMA? I consider the cord length for flexibility, too. It helps to have enough slack. I also look at how reliable my existing power sources are, including my UPS systems.

Next, I identify the necessary features and capabilities I need. I prioritize redundancy and failover capabilities, like having dual power inputs. Essential monitoring and management features are a must. I want real-time power usage data, like voltage, current, and load levels, from monitored PDUs. I also need alerts for load limits from metered PDUs. Network connectivity for remote management is key for smart PDUs. Environmental monitoring, with temperature and humidity sensors, is also a valuable feature I look for.

Selecting the Right Intelligent OEM Rack PDU

Choosing the right intelligent OEM rack PDU is a critical decision. I always consider a few key things.

- Power Capacity: I check the total wattage and amperage my equipment needs. I pick a PDU that supports my current load and allows for future growth.

- Outlet Types and Number: I match the outlets to my devices. I count how many I need now and plan for expansion. Different devices use different outlets, such as IEC C13, IEC C19, or NEMA types.

- Voltage and Regional Standards: I confirm the PDU meets my local voltage requirements and follows safety standards.

- Number of Phases: I consider if I need single-phase or three-phase power. In most data centers, the input power is 3-phase service, so I often need a 3-phase PDU.

- Number of Branch Circuits: This helps me manage power distribution effectively.

I also pay attention to specific features:

- Amperage: PDUs with 30A or higher usually need a 20A breaker. Local meters display the amperage pulled, helping me prevent circuits from getting too close to their maximum capacity and tripping breakers.

- Outlet Types: It’s crucial to determine the types of plugs used on devices in my rack, like C-13 or C-19 input cords. This ensures I have the correct ratio in my rack PDU. The number of receptacles is often balanced per phase, leading to counts like 24, 30, or 42 for 3-phase power.

- Alternating Outlets: These simplify circuit/phase balancing and cable management. This is especially true as rack densities increase.

- Locking Outlets: These secure the physical connection between IT equipment and the rPDU. They prevent accidental disconnections. Common standards include IEC320 C13 and C19.

- Environmental Monitoring: Intelligent rPDUs can incorporate sensors to proactively monitor conditions like heat and moisture within the rack.

Network Integration and Security Best Practices

Integrating intelligent rack PDUs into my existing network infrastructure requires careful planning. I follow some best practices to ensure smooth operation and strong security.

- Color-Coding: I use color-coding to streamline feed identification for my facility managers. This helps distinguish between A and B power feeds. It ensures proper load balancing and makes system maintenance more intuitive.

- Visible Light Communication (VLC): This allows for air-gapped power infrastructure. I can use a secure mobile device to scan a barcode on the GUI. This generates an accurate snapshot of power distribution data. It improves operational efficiency by replacing manual metric recording.

- Enhanced Billing Grade Accuracy: I select a metered rack PDU with 1% billing accuracy. This gives me highly accurate and comprehensive energy metering. It offers visibility to monitor and control energy usage. This optimizes power utilization and eliminates unnecessary capital expenses.

- High-Temperature Grade: Choosing PDUs with a high-temperature grade helps reduce cooling costs and enhances performance. It prevents power strip failure and subsequent equipment downtime in high-temperature data center environments.

- Locking Features: Advanced locking receptacles improve availability and security. They prevent accidental unplugging of power cords. Remotely controlled and metered PDUs offer operator flexibility and increased site security to maintain uptime.

- Intelligent Power Systems: I utilize these systems because they enable quick scaling. They support varied power profiles and provide operational telemetry for informed decision-making without physical reconfiguration. They enhance precision in power delivery, reducing risks and improving uptime for high-density AI workloads.

- Remote Monitoring: Modern PDUs with network connectivity allow for remote monitoring of power consumption and environmental conditions. This is crucial for timely interventions and maintaining power management in AI environments.

- Advanced Features: I leverage new PDU features like higher power densities and universal input for global deployment. This saves time, reduces costs, and improves overall system resiliency for complex AI workloads.

- Monitoring and Data Capture: I employ intelligent Rack PDUs and sensors to capture and transmit power and environmental data. This provides continuous oversight of critical parameters and enables immediate responses to anomalies.

Security is paramount for network connections. I implement robust security protocols and measures:

- Encryption: Secure encrypted communication is enabled by default using HTTPS and SSH. This includes TLS 1.0/1.1/1.2 with AES 128/256-bit ciphers for HTTPS. I also use public key authentication for SSH, SNMP v3 with MD5 or SHA authentication and DES or AES privacy protocols, and StartTLS for encrypted transport of user credentials.

- Password Policies: I enforce strong password requirements. These include a minimum of eight characters with mixed case, numerals, and special characters. I also require forced password changes after the first login and periodic password expiration.

- Firewall: I use IP-Based Access Control Lists (IP ACL) and Role-Based Access Control (RBAC) rules. These manage and restrict network access to PDUs.

- Defense in Depth: My measures include blocking access after repeated failed login attempts. I also time out inactive sessions, limit the use of the same login credential from multiple clients, and enforce service agreement warnings. Secure Boot ensures only trusted firmware is used.

- Certificates: I support X.509 digital certificates, including CA certificates and self-signed certificates. This ensures authorized users in secure connections and protects against man-in-the-middle attacks.

Implementing Advanced Monitoring and Alerting

I configure my intelligent rack PDUs for advanced monitoring and alerting. This gives me crucial insights and helps me react quickly to potential issues.

- Advanced Power Quality Monitoring, Metrics, and Alerting: This provides insights and accuracy, often with ±0.5% metering accuracy. It helps me with capacity planning, troubleshooting, and efficiency. I monitor total harmonic distortion, voltage dips/swells, crest factor, and power interruptions. I check these at the PDU inlet, circuit breakers, and outlets.

- Xerus™ Technology Platform: I rely on this combination of hardware and firmware. It ensures security, provides insights, and enables seamless interoperability with DCIM and other applications. It uses open architectures like SNMP, MODBUS, open REST-based APIs, and Redfish® API. It delivers high compute power, advanced alerting, and complete visibility into the power chain.

I also leverage an enhanced security suite for my monitoring systems:

- Encryption: This includes HTTPS, SSH, SNMPv3, and Smart TLS.

- Firewall: I use IP-based Access Control Lists (IP ACL) and Role Based Access Control (RBAC) rules.

- Passwords: I enforce strong passwords and password expiration.

- Certificates: I use Digital Certificates, CA Certificates, Self Signed Certificates, and US-CERT Monitoring.

- Advanced Security: This includes Secure Boot, blocking access after repeated login attempts, timing out inactive sessions, limiting the same login use from multiple clients, and enforcing restricted service agreement warnings.

Leveraging Remote Power Control for Efficiency

Remote power control features on intelligent rack PDUs are a game-changer for me. They significantly reduce response times and operational overhead. This is especially true in facilities with limited on-site staff or distributed edge locations. This capability directly enhances my operational flexibility. I can manage things efficiently from afar.

Intelligent PDUs also enhance energy efficiency. They allow my data center teams to track energy trends. We can detect unusual consumption spikes and implement strategies to optimize cooling and reduce energy waste. They integrate with DCIM or energy management platforms. This provides continuous power data for informed decisions on infrastructure upgrades, workload placement, and sustainability goals. This transforms raw power into actionable intelligence for efficient operation.

Environmental Monitoring Integration

Integrating environmental monitoring sensors with my intelligent rack PDUs offers many benefits. I find it essential for maintaining a healthy data center.

- Optimal Environmental Conditions: It helps me maintain the best conditions in my data centers.

- Real-time Alerts: It provides real-time alerts. I can address potential issues before they get worse.

- Equipment Protection: It protects my equipment and ensures uninterrupted operations.

- Risk Reduction: It reduces the risk of equipment failure and costly downtime through preventive action.

- Preventive Alerts: It helps prevent equipment failure by alerting me to potential risks like temperature and humidity changes.

- Resource Management: It simplifies resource management and supports effective capacity planning during critical situations.

- Built-in Sensors: It protects equipment from potential risks through built-in environmental sensors.

I use various types of sensors:

- Temperature sensors

- Humidity sensors

- Airflow and air pressure sensors

- Water leak detectors

- Proximity and vibration sensors

These sensors monitor my data centers and provide alerts about potential problems. These problems can jeopardize the performance and life of my IT assets. They give me accurate insights into the environmental health in and around my IT equipment racks. This enables real-time remote power metering, rack-based power quality monitoring, and environmental monitoring. This technology helps me create a smarter IT infrastructure. I can stay ahead of problems. It gives me a complete picture of data center conditions at the rack, aisle, and facility level. This reveals trends and alerts operators to real-time risks or potential threats. It enables a proactive environment for data center operations by sending environmental data to DCIM software for real-time data and trends. This helps prevent overcooling, undercooling, electrostatic discharge, corrosion, and short circuits. Ultimately, it helps my organization reduce operational costs, defer capital expenditures, improve uptime, and increase capacity for future growth. It also provides environmental monitoring and alerts managers to potential problems like the presence of water and open cabinet doors.

Intelligent rack PDUs offer deep integration with data center infrastructure management (DCIM) systems. This allows environmental data to be instantly sent to DCIM software. I can see real-time environment data and trends over time, along with other infrastructure metrics like power capacity and power quality, all on one dashboard.

Best Practices for Managing Intelligent OEM Rack PDUs

Regular Firmware Updates and Security Patches

I always make sure my intelligent PDUs stay updated. I check for firmware updates quarterly or whenever the manufacturer announces something big. These regular updates are super important. They fix security holes and make the devices work better. Applying security patches quickly is key. It stops cyberattacks, like someone bypassing my login. It also prevents my operations from stopping or devices from getting destroyed. I don’t want a compromised PDU to become an entry point into my network.

Data Analysis and Reporting for Continuous Improvement

I love how intelligent PDUs give me so much data. They help me cut costs and save power. I use outlet-level monitoring and trend analysis to see how my servers are doing. If a system crashes, I can reboot it remotely. I also power down unused IT equipment during off-hours to save energy. These PDUs collect real-time data on current, voltage, power, and energy consumption. I integrate them with my DCIM solution. This generates reports that warn me about problems and show me power load, capacity, and trends across my data center. These detailed reports help me find ways to optimize energy and improve efficiency.

Training and Documentation for Operations Teams

My team needs to know how to manage these smart devices. I make sure they get proper training. We cover things like role-based access controls for all our data center parts. They learn the authentication methods for accessing company data. We also go over physical security rules and how authorized users get access. Training staff on data center policies, like using dual-corded power systems, is crucial. We also do quality control checks. This includes verifying A/B cording, phase balancing, and installation documents.

Scalability Planning for Future Growth

I always plan for the future when I deploy an intelligent OEM rack PDU. I invest in modular in-rack PDUs. This helps me scale easily and adapt to changing power needs. Modular designs make it simple to expand, reconfigure, and customize things as my data center grows. I always think about future growth and expansion. I pick scalable solutions that can handle more power and denser racks. I look for modular designs, hot-swappable parts, and flexible setups for easy upgrades. This helps me future-proof my infrastructure.

I believe implementing intelligent OEM rack PDUs is a crucial step for great power distribution. These solutions really boost efficiency, reliability, and how I control my operations. Embracing intelligent OEM rack PDUs gives me a strong, cost-effective power setup for today’s IT needs. It just makes sense.

FAQ

How do intelligent OEM rack PDUs help me save money?

I find they save money by letting me monitor power use closely. I can turn off unused equipment remotely. This reduces energy waste and lowers my electricity bills.

Are intelligent PDUs hard to set up?

No, I don’t think so. Many come with user-friendly interfaces. They also offer network integration. This makes setup and management straightforward for me.

Can I really control individual outlets from my desk?

Yes, you absolutely can! I use switched PDUs to turn outlets on or off remotely. I can even reboot a frozen server without going to the data center. It’s super convenient.

Post time: Jan-19-2026