You know, a Basic PDU is really just a super tough, rack-mountable power strip. We design it specifically for data centers. Its main job? It simply distributes electrical power to all your IT gear right there in the rack.

Key Takeaways

- A Basic PDU is a tough power strip for data centers. It takes one power source and splits it into many outlets for IT gear.

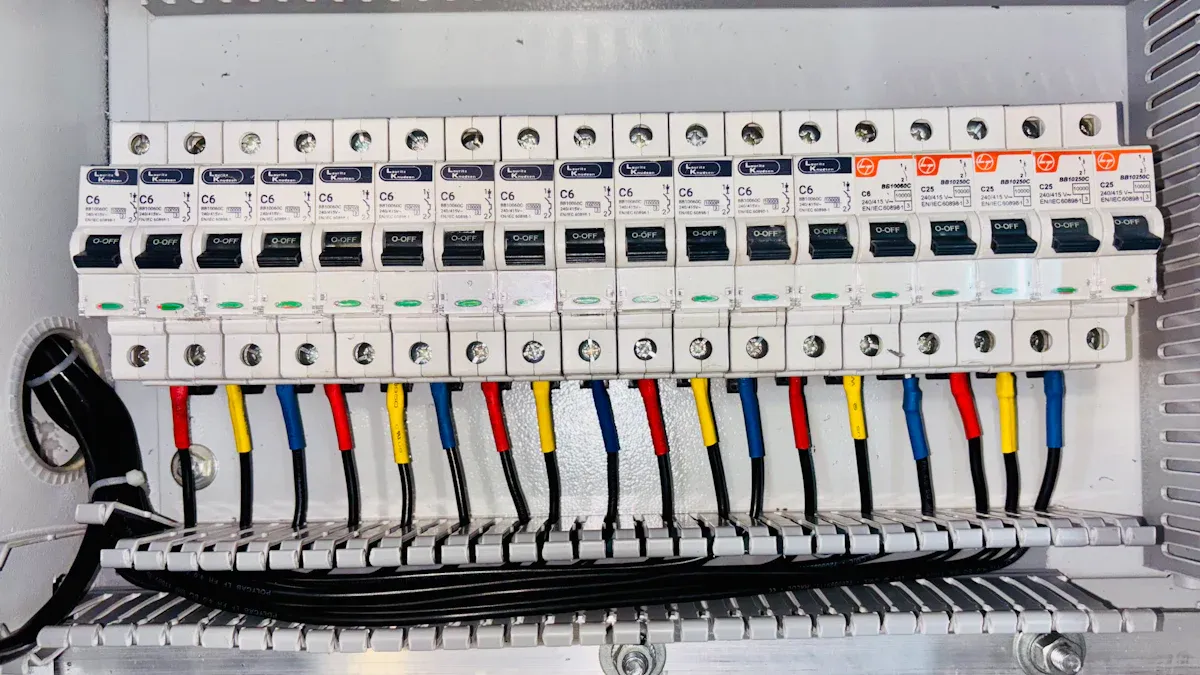

- Basic PDUs are reliable and durable. They have strong metal cases and built-in circuit breakers for safety.

- Basic PDUs are cost-effective. They provide power without extra features like monitoring or remote control.

Understanding the Basic PDU Function

Simple Power Distribution Mechanism

When I think about a Basic PDU, I picture it as the central power hub for all my rack-mounted gear. It’s not fancy, but it’s super effective. Imagine you have one big power cord coming into your rack. This PDU takes that single power source and splits it into many different outlets. This way, each server, switch, or storage device gets the power it needs without me having to run individual cables all the way back to the main power panel. It’s really just a straightforward way to get electricity from point A to multiple points B within the rack.

Input and Output Connections

Now, let’s talk about how power gets into the Basic PDU. Every PDU has an input connection, which is like its main power plug. These inputs vary a lot depending on how much power your equipment needs. For example, I’ve seen PDUs designed for smaller loads, and others for really heavy-duty setups. Check out this table; it shows some typical input specs I often encounter:

| Specification | 5 kVA | 10 kVA | 15 kVA, 1ph | 15 kVA, 3ph | 24 kVA | 37 kVA |

|---|---|---|---|---|---|---|

| Number of Inputs | 1 x 30A 1ph | 2 x 30A 1ph | 3 x 30A 1ph | 1 x 60A 3ph | 2 x 60A 3ph | 3 x 60A 3ph |

| Voltage | 200 – 240 VAC | 200 – 240 VAC | 200 – 240 VAC | 200 – 208 VAC 3ph | 200 – 208 VAC 3ph | 200 – 208 VAC 3ph |

| Frequency | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz |

| Current | 24A max. | 24A max. per input | 24A max. per input | 40A max. per phase | 34.6A max. per phase | 34.6A max. per phase |

| Data Center Receptacle | NEMA L6-30 | NEMA L6-30 | NEMA L6-30 | IEC309 60A 4 PIN 250VAC 3ph IP67 | IEC309 60A 4 PIN 250VAC 3ph IP67 | IEC309 60A 4 PIN 250VAC 3ph IP67 |

As you can see, the voltage, current, and even the type of plug can change quite a bit. It’s all about matching the PDU to the power available in your data center.

Once the power is inside the PDU, it needs to go out to your devices. This is where the output connections come in. A Basic PDU comes with a variety of outlets, so you can plug in all sorts of IT equipment. I often see these types of receptacles:

- NEMA 5-15R

- NEMA 5-20R

- NEMA L5-30R

- NEMA L6-30R

- IEC 60320 receptacles

And sometimes, a single PDU will have a mix of these outlets to handle different device power cords. Here’s a quick look at some common outlet configurations I’ve seen:

| PDU Configuration | Outlet Types |

|---|---|

| Basic PDU | 10 – NEMA 5-15R |

| Basic PDU | 2 – IEC-320 C19, 6 – IEC-320 C13 |

| Basic PDU | 12 – NEMA 5-20R |

This variety ensures I can connect almost any piece of standard IT equipment directly to the PDU.

Core Functionality of a Basic PDU

Beyond just splitting power, a Basic PDU has some really important core functions, especially when it comes to safety and reliability. I always appreciate how these units are built to protect my valuable equipment.

First, they usually include built-in circuit breakers. These are super important because they act like a safety net. If too much power tries to flow through, or if there’s a short circuit, the breaker trips. This instantly cuts power and prevents damage to my servers or even fires.

Another thing I notice is that many basic PDU models don’t have an on/off switch. This might seem odd at first, but it’s actually a smart design choice. It prevents anyone from accidentally turning off critical equipment like routers or servers. This ensures my devices stay powered on, which is crucial for continuous operations.

Finally, I always look at the construction. These PDUs are tough! They use heavy-duty copper wires and thick insulation. This helps prevent overheating, which is a big deal in a data center. The outer jacket is also really strong, so it can handle wear and tear, heat, and even minor bumps. This durable build means I can rely on them to deliver power safely and consistently, day in and day out.

The Importance of a Basic PDU in Data Centers

Reliability and Durability

When I think about the backbone of any data center, I always consider the reliability of its power distribution. A Basic PDU might seem simple, but its reliability and durability are incredibly important. I’ve seen these units withstand a lot, and that’s because they are built to last.

Industry reviews describe similar models as “no-frills devices” that are “sturdy and robust” due to their metallic, industrial-grade cases.

I find this description spot on. They aren’t flashy, but they are tough. The materials and construction methods really make a difference.

- Chassis Construction: Most PDUs feature robust construction. They often use heavy-gauge steel or aluminum. This gives them superior durability and protects all the important internal components.

- Heat Dissipation: These metal housings also help a lot with heat. They contribute to efficient heat dissipation, which is crucial in a hot data center.

- Surface Finish: Manufacturers apply a powder-coated finish. This helps resist corrosion and wear, keeping the unit’s integrity over time.

- Structural Integrity: Using high-quality materials prevents bending or cracking under stress. This is vital in busy data center environments where things can get bumped around.

- Impact on Lifespan: The choice of materials directly influences the PDU’s lifespan. It also affects its ability to endure harsh conditions.

I also know that manufacturers use durable materials like steel or aluminum for the PDU chassis. This safeguards internal components from physical harm. They also incorporate high-quality internal wiring and robust outlet receptacles. This ensures long-term reliability. These materials are chosen to withstand the demanding conditions typically found in data center environments. I even hear about future developments using plastics and metals with enhanced heat and corrosion resistance. This will extend lifespan and reduce how often we need to replace them. PDUs are being designed to operate in harsher environments, offering protection against dust, humidity, and wider temperature ranges. This is crucial for edge computing and industrial data centers.

Cost-Effectiveness for Power Distribution

One of the biggest reasons I often recommend a Basic PDU is its cost-effectiveness. When you’re setting up a data center, every dollar counts. These units provide essential power distribution without breaking the bank.

Let me show you how their initial cost compares to other PDU types:

| PDU Type | Initial Cost | Key Features |

|---|---|---|

| Basic PDUs | Low-cost | Distributes power, no monitoring/management |

| Metered PDUs | More expensive than basic | Basic monitoring (voltage, current, power consumption) |

| Monitored PDUs | More expensive than metered | Remote access and control via network/web interface, same monitoring as metered |

| Switched PDUs | Most expensive | All features of monitored PDUs plus remote switching of individual outlets |

As you can see, Basic PDUs have lower acquisition costs. Switched PDUs tend to be the most expensive because of their advanced features. This chart really highlights the difference:

I’ve seen models like the APC Rack PDU AP9571A for around $399.99, or the AP9568 for $289.99. These budget-friendly options, sometimes even including basic metering, offer essential power management at a lower price point. For small businesses or startups, this affordability is a huge advantage. They provide a solid foundation for reliable power distribution without the need for advanced monitoring. This makes them a very cost-effective choice for many setups.

Foundational Power Delivery

I often think of Basic PDUs as the workhorses of power delivery. They are perfect for situations where you just need straightforward, reliable power. They don’t have all the bells and whistles of more advanced units, but that’s exactly why they are so good for certain environments.

They are ideal for situations where only fundamental power distribution is needed. You don’t need advanced management or monitoring capabilities. They are a cost-effective and simple-to-deploy solution for small data centers or less critical applications.

Here are some specific scenarios where I find them most appropriate:

| Scenario | Reason for Suitability |

|---|---|

| Small server rooms | Affordable and easy to use without advanced features. |

| Office setups | Cost-effective and straightforward power delivery. |

| Low-density environments | Compact size saves rack space, suitable for simple needs. |

| Environments without monitoring | No need for advanced monitoring or remote control. |

| Small businesses and startups | Affordability and ease of use. |

| Setups with minimal power management needs | No requirement for remote monitoring or environmental tracking. |

When I’m choosing a PDU, I always consider a few key indicators. The load capacity is essential. It handles significant power loads to prevent overheating and equipment failure. The form factor, whether it’s rack-mounted or standalone, affects space optimization and organization. I also make sure the outlets and plug types ensure compatibility and efficiency. This means matching the number and types of outlets to my devices. Finally, surge protection and safety features are a must. They protect against electrical surges and include overload protection and circuit breakers. These units excel in high-demand settings like data centers and workshops. They provide that foundational power delivery I can always count on.

Basic PDU vs. Advanced PDU Types

When I talk about power distribution, I often get asked about the differences between a Basic PDU and its more advanced cousins. It’s like comparing a reliable work truck to a high-tech, smart vehicle. Each has its place, but they offer very different capabilities.

Basic PDU vs. Metered PDU

I see a big difference between a Basic PDU and a Metered PDU, especially when it comes to knowing what’s happening with my power. A Basic PDU just distributes power, much like a power strip, without collecting any data. It’s simple and gets the job done.

However, a Metered PDU steps it up. It includes a built-in current meter that locally monitors the load level. This means I can see real-time metrics like voltage, current, and power factor right there on the unit. It even offers user-defined alarms for potential overloads, which is a great safety net.

| Feature | Basic PDUs | Metered PDUs |

|---|---|---|

| Primary Function | Power distribution only | Power distribution with real-time monitoring |

| Monitoring Capabilities | None | Real-time monitoring of metrics like voltage, current, and power factor |

| Alarms | No | User-defined alarms for potential overloads |

While Metered PDUs give me real-time visibility into power consumption, they usually don’t connect to a data network. So, I can’t easily accumulate data for historical analysis or remote monitoring without manual checks. They do require a bit more setup, including network configuration if I want remote monitoring, but the long-term operational savings from reduced energy costs and less downtime often make them worth the initial investment.

Basic PDU vs. Switched PDU

Moving beyond just monitoring, Switched PDUs introduce a whole new level of control that a Basic PDU simply can’t match. With a Switched PDU, I get remote on/off control of specific devices through software commands. This is incredibly useful!

I can remotely reboot unresponsive servers or schedule power cycles for equipment, which saves me a trip to the data center. This remote power management helps reduce downtime and makes my operations much more efficient. Switched PDUs are perfect for remote data centers or large facilities where I need quick and easy power cycling. They also help limit power usage at the outlet to prevent accidental overloads.

Basic PDU vs. Intelligent PDU

Now, if I want the ultimate in power management, I look to Intelligent PDUs. These units combine all the features of Metered and Switched PDUs and add even more advanced capabilities. They offer comprehensive remote monitoring and management, giving me real-time data on power usage, temperature, and other environmental parameters.

Intelligent PDUs allow me to:

- Monitor metrics like voltage, current, active power, and energy.

- Control individual outlets via the network for power cycling and sequencing.

- Integrate with DCIM software for a single-pane-of-glass view of my power data.

- Support environmental sensors for temperature and humidity.

While Intelligent PDUs have a higher initial cost compared to a Basic Pdu, their advanced features can lead to significant long-term savings through optimized energy usage and improved operational efficiency. It’s a trade-off between upfront cost and powerful functionality.

I believe Basic PDUs are truly essential. They provide reliable power distribution for my data center operations. I see them as a foundational component for all my straightforward power needs. Their simplicity and cost-effectiveness make them indispensable in many setups. I really appreciate their value.

FAQ

What is the main purpose of a Basic PDU?

I use a Basic PDU to distribute electrical power to my IT equipment within a rack. It takes one power source and splits it into many outlets.

Why would I choose a Basic PDU over a more advanced one?

I choose a Basic PDU for its cost-effectiveness and simplicity. It’s perfect when I only need straightforward power distribution without advanced monitoring or control features.

Do Basic PDUs offer any safety features?

Yes, they do! I find most Basic PDUs include built-in circuit breakers. These protect my equipment from overloads and short circuits, which is really important.

Post time: Dec-08-2025